Alloy Wheels - To Know More

When you want to buy your new shiny alloy wheels, dealer will start to impress you with a lot of strange words. One of the major stumbling blocks for novices is the use of terminology - it can be really confusing. So, I will try to explain to you few of most used and most important terms in business.

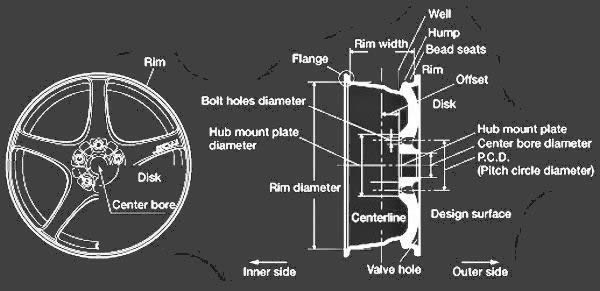

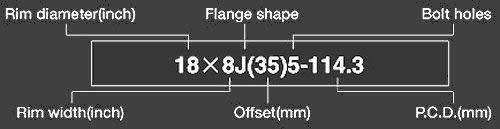

P.C.D. (Pitch Circle Diameter)

Fitting alloy wheels is relatively straightforward, but if you have doubts you should use a trained mechanic. It is of course important alloy wheels are properly seated for safety. The Pitch Circle Diameter is the diameter of an imaginary circle drawn through the centre of the bolt holes. It will help you work out how many bolts and studs the alloy wheel will have. The P.C.D. of the wheel should match the P.C.D. that your car came with as standard.

P.C.D. is measured in mm. e.g.: 4x100 means the wheel has 4 bolt holes and the diameter of the imaginary circle through the bolt holes is 100mm. These details are shown in the Wheel Specifications label on the wheel itself.

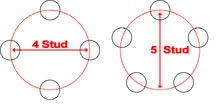

The Wheel Offset

What is an offset? An offset is often engraved onto the Wheel Specifications label on the wheel itself, on the back of the wheel or behind the centre cap and it means the distance between the wheel's centre line and the hub mounting face at the back of the wheel. The offset is commonly, but not always shown as the letters ET followed by a number, e.g.: ET49. The offset is always measured in mm.

If you take a wheel and cut it in half and draw a line down the centre of the width of the alloy wheel the offset will be the distance between the back face (mounting face) of the wheel and the centre line that you have just drawn.

If you have a wheel that has a mounting face at the front of the wheel, this is called a Positive Offset Wheel. If you have a front wheel drive, this is likely to be the kind of wheels you have. Zero Offset wheels have the mounting face level with the centerline of the wheel and Negative Offset wheels have the mounting face towards the rear of the wheel.

Each car has its optimum offset and a range within which the offset can be for the wheel to fit the car properly.

If the offset is too low for the range allowed, the wheel could stick out from the side of the car, if too high from what it should be the wheel may catch on the suspension or bodywork as it will be too far under the car.

This is due to the fact that if you put a wheel on your hub with a higher offset than before, the wheels bolting face will have to move further under the car to meet the hub, in extreme cases causing the wheel to sit too far under.

Using spacers to change the offset

If the offset of a wheel is too high for your vehicle, in most cases spacers can be used to reduce the offset, pushing the wheel further out to make it sit correctly in relation to the cars bodywork and arches. This allows you to fit wheels to your car that aren't initially made in a direct fit, widening your choice of wheels and is completely safe and road legal to do.

However, if the offset of a wheel is too low compared to the offset your car needs, there is no way of rectifying this as they will already sit too far out from where they should be and can't be brought back under the car.

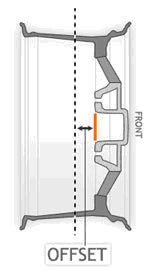

Wheel Width and Diameter

The alloy wheel size is shown as follows:

Wheel diameter x Wheel width - e.g.: 15x6.5J.

The width is the section between the tire mounting flanges on the wheel / the diameter is the height of the wheel.

Wheel Centre Bore and Spigot Rings

Made from either plastic or metal, Spigot Rings allow perfect fitment and alignment of your alloy wheels when the centre bore differs from the hub lip diameter.

When it comes to buying the right sized alloy wheels you need to ensure you have the correct nuts and bolts. A centre bore is the size of the hole at the back of the wheel which the hub fits into - clearly this need to match and fit property for the wheel to seat.

Wheel Centre Bore is the diameter of the centre hole in the back of the wheel. It is crucial that the centre bore of the wheel locates properly on the lip on the hub of the vehicle to get a perfect fit. Most wheels work on a spigot ring locating system because most wheels have a centre bore bigger than the size of the hub lip allowing them to fit a wider range of cars. A spigot ring is fitted into the back of the wheel with an outer diameter the size of the centre bore, and an inner diameter the size of the hub lip to allow the wheel to be correctly located onto the hub and to fit tightly onto the vehicle for safety and comfort.

There are wheels that are hub centric i.e. the wheel is manufactured with a centre bore to fit precisely onto a specific vehicle and in these cases spigot rings would not be unnecessary.

If the wheel does not locate onto the vehicle's hub assembly correctly it will cause a vibration on the steering wheel and can lead to bad wear on the tires and bearings so if spigot rings are provided you MUST use them, and they are supplied if necessary.

Why to Consider Alloy Wheels?

Should you consider alloy wheels for your car?

The majority of car manufacturers use steel wheels for everyday cars because they are resilient and cheap. But steel wheels are also heavier, uglier and smaller than alloy wheels. Alloy wheels are cast from a mixture of aluminium which has the benefits of being light weight and good at dissipating heat.

If you love cars, you'll know that snazzy alloy wheels can help improve a car's image and even its handling. Alloy wheels can make your car stand out from the crowd, so if you haven't considered alloy wheels before, here are some reasons why you should. The other main reason car enthusiasts prefer alloy wheels aside from looking good, is because they provide superior strength with dramatic weight reductions for an overall high performance wheel. Racing cars, sports cars and other high performance vehicles all benefit from using alloy wheels.

Why to fit Alloy Wheels?

1. A set of alloy wheels will improve the appearance of your vehicle and in doing so will make your vehicle stand out from the crowd.

2. Alloy wheels will reduce the unsprung weight of a vehicle fitted with standard steel wheels. The benefit of reduced unsprung weight is more precise steering as well as a nominal reduction in fuel consumption.

3. Alloy is an excellent conductor of heat, improving heat dissipation from the brakes, reducing the risk of brake failure under demanding driving conditions.

4. There will be a noticeable improvement in the steering response and road holding, especially when cornering!

Choosing right alloy wheels

Firstly the wheel must appeal to you.

In order for the wheel to offer the benefits expected from it, it must be manufactured to fit properly. There are four aspects that are critical for precise fitment namely:

• P.C.D. (Pitch Circle Diameter)

• Offset

• Centre Bore

• Diameter

Up-stepping

If you want to increase the wheel-diameter and reduce the tire exposed, this is called up stepping. Up stepping with alloy wheels looks smart and can increase the handling of your car.

Fitting alloy wheels

When it comes to fitting alloy wheels then, you should make sure that you have the right bolts of the right diameters - if in doubt, ask your alloy wheel supplier for this information.

Alloy wheels - Beauty at a price

You should however ensure that you maintain your alloy wheels and keep them clean from dust and grime. Simply use a mild soap solution to clean your alloy wheels. You should also ensure you drive carefully and improve your parking so you don't damage your alloy wheels on the curb.

You should however ensure that you maintain your alloy wheels and keep them clean from dust and grime. Simply use a mild soap solution to clean your alloy wheels. You should also ensure you drive carefully and improve your parking so you don't damage your alloy wheels on the curb.

Like anything valuable and beautiful in life, alloy wheels can be high maintenance. It is of course worth it - nothing looks hotter than sleek, sporty, shiny alloy wheels with a low profile tire.

But low profile tires and shiny alloy wheels are more at risk to environmental and road hazards and curbs can be disastrous.

Enkei alloy Wheels R1 C3

Although they look great you have to be prepared to spend money when it comes to alloy wheels, which explains why alloy wheels are targeted by so many car thieves. Bad parking and scraping the curb could be potentially cosmetically devastating to your alloy wheels.

So, there are many bonuses fitting alloy wheels, the image don't come without a trade off. Alloy wheels aren't as durable as steel even if they aren't as bland. They can be damaged if you are a bad parker and hit the curb - and it can be expensive to buy a whole new set just because one has a mark. If you love alloy wheels though, don't despair - online car accessory and alloy wheel shops have extensive ranges in stock at competitive prices.

Vulnerable areas on your alloy wheels include:

Vulnerable areas on your alloy wheels include:

- The rim on alloy wheels is at risk from potholes or curbs for example, which could cause bends or dents.

- The rim lip could be chipped by a big pothole - this could compromise the safety of the car and cause air leakage from tire.

- It can be costly replacing an alloy wheel if you can't find one that matches the rest - you could end up forking out for a whole new set of alloy wheels.

Alloy Wheels - Beware repairs

If you do damage your alloy wheels it could be tempting to repair the wheel in question if it's not too serious. But there is a debate about whether or not it is wise to repair alloy wheels. Although wheel repair may be a more economical option, it's important to put safety first - buying new alloy wheels is the only real safe option.

If wheel is not repaired correctly, material became brittle and can easy brake with load.

Alloy wheel repairs are another option if you don't want to shell out more cash than you need to. When it comes to cosmetic repairs on alloy wheels such as a few scuffs, than this is a sensible option. But some experts are unsure about more serious damage such as aluminium rim repairs and believe defects in aluminium are a major challenge for engineers and mechanics. There are concerns that repairs could negatively impact on tire and suspension wear.

If you have substantial damage to your alloy wheels or you are unsure how bad the damage is, it is always better to be safe than sorry and invest in new alloy wheels.

Shop online for alloy wheels

However just because alloy wheels can be temperamental to maintain, doesn't mean they aren't worth the effort - in fact it's what makes them so desirable to car enthusiasts. If you want the effect of alloy wheels but not the high price tag, there are plenty of online shops that offer some incredibly competitive prices on a wide range of alloy wheels. Online shops also tend to be the best places to find one-off designs or one off alloy wheels if you have just damaged one wheel and don't want to buy a whole brand new set.

However just because alloy wheels can be temperamental to maintain, doesn't mean they aren't worth the effort - in fact it's what makes them so desirable to car enthusiasts. If you want the effect of alloy wheels but not the high price tag, there are plenty of online shops that offer some incredibly competitive prices on a wide range of alloy wheels. Online shops also tend to be the best places to find one-off designs or one off alloy wheels if you have just damaged one wheel and don't want to buy a whole brand new set.

Before fitting tires on all aftermarket wheels you MUST check:

1.The stud/bolt hole pattern is correct.

2.That the nut/bolt location seating is correct.

3.That the thread form is correct (fits nuts without alloy wheels).

4.That the stud length is adequate for minimum thread penetration of approximately 1 x stud diameter and not too long as to permit bottoming of the stud in the nut or that the thread penetration of the bolt protrudes through the hub housing to cause damage to internal brake or hub components.

5.That the threads are rust free, and not over lubricated

6.When sleeve nuts are used, that the shank diameter is correct and that the bearing washers are always used.

7.That the alloy wheel fits freely on to the hub without interference, and that there are no screws, rivets or retaining clips which may interfere with a firm flat location of the hub against the wheel mounting face.

8.That the alloy wheel rotates freely and truly on both front and rear hubs.

9.When fastened to the hub, that no part of the wheel can make contact with the brake drums or calipers; or any other part of the steering or suspension.

When Fitting the Tire Make Sure:

1.That the alloy wheel rim size is compatible with tire size.

2.Be wary of scratching the protective lacquer coating. (On aluminium wheels and some chrome wheels) Aluminium corrodes very easily once exposed to atmosphere, water, road salt or corrosive acid based alloy wheel cleaners and chemicals.

3.Where possible always use the adhesive type of balance weight, as these help to avoid scratching of the alloy wheel finish.

4.That the alloy wheel and tire assembly does not contact any part of the suspension, body work or internal hub components (brakes, sensors etc) by carrying out full bump and lock to lock tests as well as a full visual inspection of the back / hub section of the alloy wheel fixing assembly before driving away from the fitting bay.