Torsion bar

Most of the racing cars suspension systems are similar, but they take two forms. The first is the traditional coil spring setup, common in most modern cars. The second is the torsion bar setup. A torsion bar does the same job as a spring but is more compact. Both forms of suspension systems are mounted on the chassis above and in front of the drivers legs, at the front of the car, and on top of the gearbox at the rear. Torsion bar is now in use in all Formula 1 cars.

Torsion bar, this is in fact a tube or bar and acts as a spring, it replaces the conventional coil spring. Torsion bars are made of metal (generally some form of steel) with shorts splined ends to connect to the rocker on one end, and chassis on other. Where a coil spring provides stiffness when compressed, a torsion bar provide stiffness when twisted. The Rate of stiffness of the bar depends on its material, length and inner\outer shaft diameters.

|

|

|

The springs or torsion bars are the parts of the suspension that actually absorb the bumps. In simple terms, the softer the suspension on the car, the quicker it will travel through a corner. This has the adverse effect of making the car less sensitive to the drivers input, causing sloppy handling. A harder sprung car will have less mechanical grip through the corner, but the handling will be more sensitive and more direct, ideal for circuits such as Monaco where the drivers must be inch perfect between the barriers.

Torsion bar in gray color

On the front, they are almost always mounted along the car, one for each side of the suspension. The springing motion is provided by the metal bar's resistance to twisting. In the typical torsion bar pushrod set up described at picture above the torsion bars pass through the centre of the rockers and fix to the front of the chassis. The Rocker pivots on the torsion bar. The push rod pushed the rocker and twists the torsion bar to provide the spring in the suspension, the rocker then compresses the damper and operates the antiroll bar if the car is in roll.

F1 dampers and torsion bar are made by specialist companies like Eibach, Koni and Sachs with springs often designed in part by the F1 teams to suit certain characteristics.

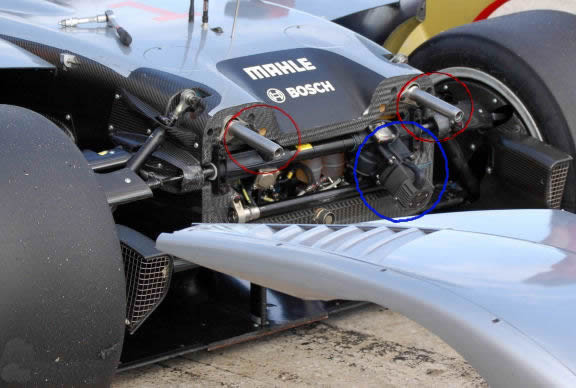

Sebring 2009, LMP1 Prototype Audi R15's horizontally mounted torsion bars in red circles, and the electronic power steering unit in blue circle

Mike Callahan, of the ALMS spotter's guide, gives us a look at the Audi R15's front end. We can see horizontally mounted torsion bars (red circles) and the electronic power steering unit (blue circle). Front suspension members are individually shrouded as they are at the rear. Brake ducting is as on the R10 in that it's via upright mounted backing plates with ducts mounted to the backing plates. Layout is similar to Formula 1 front suspension.

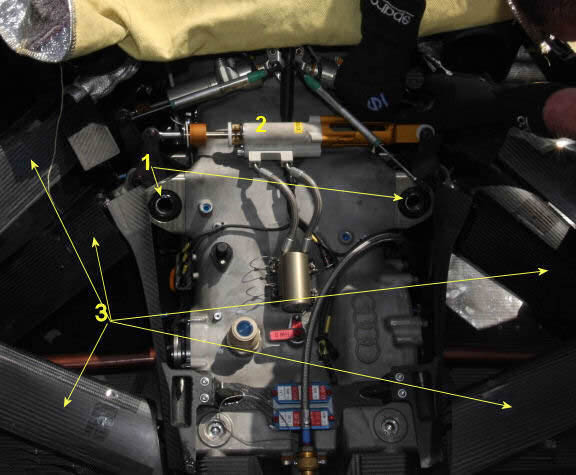

Numbered as 1 you can se rear vertically mounted torsion bars on Audi R15, with Number 2 horizontally mounted third damper, and with number 3 suspension members, similar as in Formula 1 car

The R15's rear suspension is somewhat similar in general layout to the Audi's old model R10's. We can see the (now) near vertical torsion bars (1) as well as the through-shaft "3rd-spring" damper on top (2). All the rear suspension members (3) are made of carbon fiber. The duct ahead of the rear wheel draws air into this area of the car and out the back to reduce base drag. The shrouded suspension members helps to streamline the air's route through the duct. It also appears that the sides of the gearbox are shrouded as well to reduce internal drag. Layout is also similar to Formula 1 rear suspension.

Back to the top of the page