Clutch

A clutch is a mechanism for transmitting rotation, which can be engaged and disengaged. Clutches are useful in cars and other devices that have two rotating shafts. In these devices, one shaft is typically driven by a motor, and the other shaft drives another device like gearbox in case of cars.

The gasoline or diesel engine has a limited output bandwidth of approximately 1000 to 6000 or more RPM. Internal combustion engine can't operate from 0 RPM (like an electric motor), so it needs a device (the clutch) to disconnect it from the drive train so that it can idle while the car, or any other equipement driven by ICE, is at a standstill.

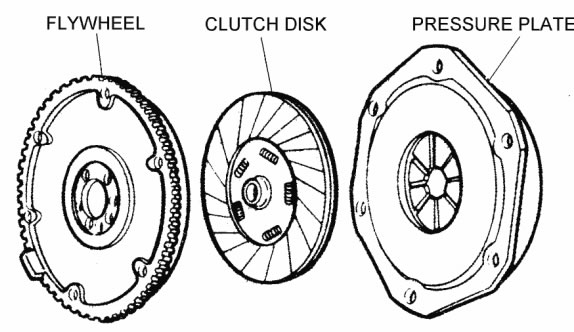

The clutch is integrated with the engine's flywheel. There is a disk with friction material, similar to a brake pad, which is connected to the transmission input shaft on a sliding  spline. This disk is surrounded by the flywheel surface on one side, and the pressure plate surface on the other side. The pressure plate is spring loaded to squeeze the clutch disk against the flywheel, effectively making a solid connection. The pressure plate can be moved by pressing down on the clutch pedal. This releases the coupling pressure between the flywheel and the clutch disk so that they can rotate independently.

spline. This disk is surrounded by the flywheel surface on one side, and the pressure plate surface on the other side. The pressure plate is spring loaded to squeeze the clutch disk against the flywheel, effectively making a solid connection. The pressure plate can be moved by pressing down on the clutch pedal. This releases the coupling pressure between the flywheel and the clutch disk so that they can rotate independently.

There are three states the clutch can be in:

CLUTCH DISENGAGED (pedal pressed down): The engine flywheel and the clutch disk can rotate independently. No power is being transferred.

CLUTCH SLIPPING (pedal brought up just to the point that the clutch starts to grab): The engine flywheel and the clutch disk are still rotating at different speeds, but some power is still being transferred. If the clutch pedal is continued to be brought up properly, the speed of the engine and the clutch disk will be brought together. This is the state that clutch wear occurs.

CLUTCH ENGAGED (pedal up): The engine flywheel and the clutch disk are locked together. Full power is being transferred, and no clutch wear is occurring.

There are many different vehicle clutch designs but most (at least one we are interested in) are based on one or, in case of Formula 1, more friction discs, pressed tightly together or against a flywheel using springs. The friction material varies in composition depending on whether the clutch is dry or wet, and on other considerations. Clutches found in heavy duty applications such as trucks and competition cars use ceramic or carbon plates that have a greatly increased friction coefficient. However these have a "grabby" action and are unsuitable for road cars.

The spring pressure is released when the clutch pedal is depressed thus either pushing or pulling the diaphragm of the pressure plate, depending on type, and the friction plate is released and allowed to rotate freely.

Clutch, in F1 case, consist of three (or more) plates which, when held together with a strong compressive force, provide a perfect connection between driveshaft and engine. When the clutch paddle is pulled by driver (in F1 terms, the clutch is a paddle on the steering wheel), on-board computer give a signal to hydraulic actuator, and the compressive force on the clutch plates is released and the plate that is connected to the engine can spin freely, while the one attached to the driveshaft and gear wheels in the gearbox remains still. This allows a new gear to be selected before the clutch pedal is let free, and the pressure on the clutch plates holds them together once again. Same happened when onboard computer give a command to open a clutch during gear change.

In the world of the F1 semi-automatic and seamless gearbox's, of course, there is no need for the driver to even think about this – everything is electronically controlled! All the driver is required to do is to pull gearshift paddle on the back of the steering wheel when he wants to change up or down a gear, and the electronics controlling the gearbox and clutch do the rest. The advantages here, over and above the fact that the driver can keep his hands on the wheel at all times, is that the whole process can be done in a split second (much quicker than a manual clutch could be operated) and also that the wear on the clutch pads is less because it is never held half-on, and so this increases reliability.

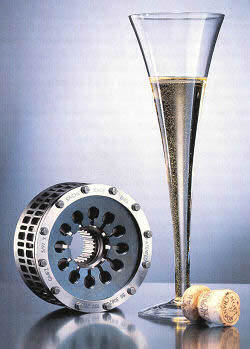

The wineglass and champagne bottle cork provide a remarkable

prospective for this ZF Sachs Formula 1 clutch. Though tiny, only

111 mm in diameter, it can transmit more than 900 horse power.

For safety reasons all cars must have a means of disengaging the clutch that is operable from outside the cockpit by marshals. This control is usually situated just ahead of the cockpit opening and is marked on the car's body by a red letter "N" within a white circle.

To improve your knowledge about road car clutches, check my article here.

Two manufacturers, AP racing and ZF Sachs produce Carbon/Carbon F1 clutches.