2014 Formula 1 Rule change

New

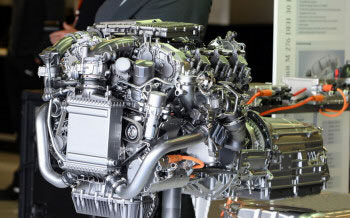

Power Unit (1.6 V6) with ERS

This article is now mainly outdated and is talking about Power Unit of 2014 and few years later. from 2017 things are a bit different, but most of facts are the same and can be applied to modern engines. Outdated things are marked red.

First to clear one thing: fans are a bit disappointed because of sound, fragility and fuel saving and they blaming Berny Eckleston and FIA. But in reality, teams wanted and agreed to these rules changes and Renault wanted even smaller engines (1.4 V6).

While the hybrid systems introduced for 2014 are altogether more far-reaching, the idea of the engine as a standalone source of propulsion in Formula One competition was consigned to history several years ago through the introduction of KERS (Kinetic Energy Recovery System) hybrid power in 2009 and from 2011 through 2013, with the Mercedes-powered McLaren of Lewis Hamilton taking the first ever hybrid F1 victory at the 2009 Hungarian Grand Prix.

So, starting with the 2014 season, Formula 1 regulations shift drastically, and the most significant change is the switch from 2.4-liter normally aspirated V8 engines to 1.6-liter direct-injected turbocharged V6 units. 1,6 turbocharged, and you kind of expect they'll be pretty similar to the 1.6-liter turbocharged engines in your family car nowadays. Not even close.

F1 in 2014 is a more technically challenging sport than ever before. The new efficiency formula and turbo hybrid engines, with restrictions to both maximum fuel flow and total fuel usage, require an intellectual engagement from the drivers of considerable depth.

The 2014 energy recovery system (ERS) boosted F1 cars are extremely complex systems. The new engine represents a significant departure from the 2.4-liter, naturally aspirated V-8s that have been used in Formula 1 since 2006. The FIA says its goal was to bring Formula 1 technologies closer to those of production cars basic principles and right in line with trends we're seeing on showroom floors: reduced displacement, turbocharging, and increased electrification. And just like in production cars, these changes are being made in the name of efficiency and greenness. But more spectacular racing, with F1 cars having more power than grip, sometimes exceeding traction circle on corner exits and an opportunity to showcase technology and innovation, will put F1 engines back at the cutting edge. Although the current generation of F1 cars has already embraced hybrid technology with KERS, the sport is poised for a technological revolution, which will push environmentally relevant technology right to the fore. In an effort to reduce fuel consumption by up to 35% the FIA have introduced changes to the technical regulations to significantly increase harvesting of normally lost energy. The entire thrust of the sport in 2014 will be to deliver cars that are capable of racing at today's speeds whilst using less. Furthermore, built into the regulatory roadmap is a fuel consumption descalator that will require the teams to deliver competitive racing with less fuel each year thereafter.

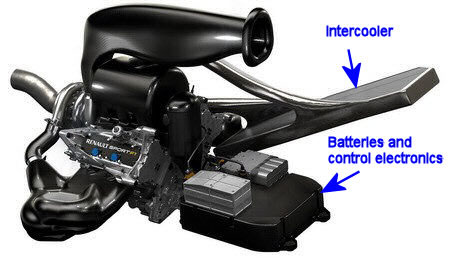

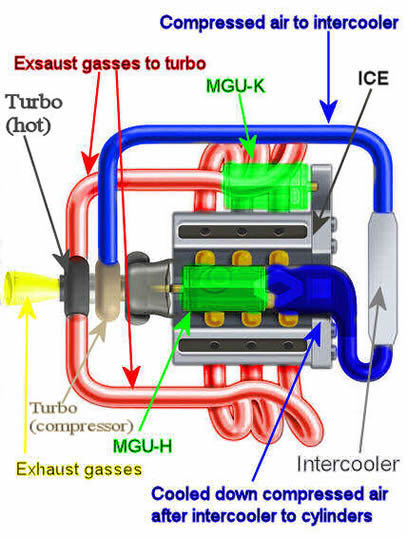

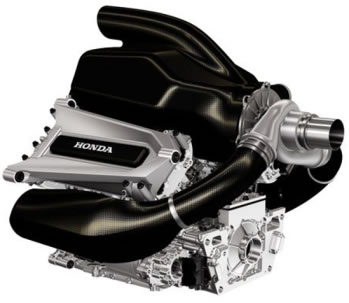

Without getting too technical, there is no more "engine" in FIA technical regulations. Article 1.22 of the Technical Regulations now refers to what is called a 'Power Unit'. This comprises an ICE (Internal Combustion Engine). In fact that ICE is just one of six components of the power unit, along with the motor generator unit-kinetic (MGU-K), which harvests energy when the car is braking, the motor generator unit-heat (MGU-H), which harvests heat energy from the turbo, the battery or “energy store - ES”, the turbocharger and the control electronics.

But why to change the name to Power Unit? 2013 V8 essentially features additionally added, "bolt-on" KERS Hybrid system that was added during the engine's life, and after development of engine was actually frozen. The 2014 Power Unit has been designed with fully integrated hybrid systems from the very beginning and it can't work properly without it.

Again, the internal combustion part of the engine (ICE) will be tightly controlled, to the point of limiting fuel flow at specific RPM but, crucially, the new ERS part of the power unit will allow for creative thinking by engine techs. The new heart of the powertrain is a 1.6-liter, 90-degree V-6 now using direct injection and making more than 600 horsepower. Engine revs are capped at 15,000 rpm (versus 18,000 rpm for the current V-8s) and a single exhaust replaces the outgoing V-8's dual-exhaust setup. The V6 units themselves will of course be shorter than their older V8 counterparts but weight of the power units will exceed that of the older engines, from 95Kg to 145Kg, which will effect centre of gravity. 145kg will be the weight of the entire power unit including ICE with turbocharger, MGU-K and MGU-H. New ICE can use direct injection of the fuel at maximum pressure of 500 bar. The FIA have also raised the position of the crankshaft for 2014 to 90mm above the reference plane whereas the V8 has been at 58mm (32mm difference). In line with this the centre of gravity of the engine previously lay at a point no higher than 165mm from the reference plane whilst in 2014 this is raised to 200mm. While fuel consumption is currently (before 2014) unregulated, new cars will be limited to 100Kg (about 135 -140 litres, 36 gallons) of fuel per race and a maximum flow rate of 100kg per hour in 2014 and beyond, designed to encourage steady use of fuel. The fuel flow is measured using the fuel flow sensor (Art. 5.10.3 & 5.10.4 of the Technical Regulations) which is homologated by the FIA and owned and operated by the team. This links power output to fuel consumption, meaning drivers and strategists will have another variable to play with to make sure they don't empty their tanks too quickly, making optimisation of every gram of fuel vital for cars to go as fast as possible on a given quantity of fuel. But I don't see a big problem there. Teams already learnt enough about managing fuel, and they been doing it for years. It’s always been a target to finish the race with a few hundred grams of fuel. It’s nothing different. I don’t see it as a big issue.

F1 engine manufacturers stopped issuing details of their power outputs during the 1990s. But since F1 engine technology was frozen with the introduction of the V8s in 2006, the consensus view is that V8 engines have around 750bhp. Their replacements are expected to produce 650hp – with addition of further expected power of 161bhp from ERS, so more than old V8. I know, cars will be also 50 kg heavier. Problem for drivers will be the delivery of torque that far supersedes it's V8 counterpart. Torque will be available at lower rpm making power available much sooner. We have to remember we are talking about two different types of Engine – naturally aspirated V8 and V6 Turbo, and the latter has a better VE (Volumetric Efficiency). To work with some crude figures we can estimate that the current V8's produce around 300Nm at 18,000rpm and around 750hp. V6 Turbo will produce around 400 Nm of torque and around 650bhp at 10,500rpm. This increase in torque will make for great viewing as the drivers try to grapple with the extra low-end power, because they have become used to a degree of refinement in the current V8 engines they will not enjoy with the new ones – at least, not at first. Furthermore the challenge will extend to tire supplier who will be required to provide tires that are capable of handling more torque sliding. Traction will be crucial.

F1 engine manufacturers stopped issuing details of their power outputs during the 1990s. But since F1 engine technology was frozen with the introduction of the V8s in 2006, the consensus view is that V8 engines have around 750bhp. Their replacements are expected to produce 650hp – with addition of further expected power of 161bhp from ERS, so more than old V8. I know, cars will be also 50 kg heavier. Problem for drivers will be the delivery of torque that far supersedes it's V8 counterpart. Torque will be available at lower rpm making power available much sooner. We have to remember we are talking about two different types of Engine – naturally aspirated V8 and V6 Turbo, and the latter has a better VE (Volumetric Efficiency). To work with some crude figures we can estimate that the current V8's produce around 300Nm at 18,000rpm and around 750hp. V6 Turbo will produce around 400 Nm of torque and around 650bhp at 10,500rpm. This increase in torque will make for great viewing as the drivers try to grapple with the extra low-end power, because they have become used to a degree of refinement in the current V8 engines they will not enjoy with the new ones – at least, not at first. Furthermore the challenge will extend to tire supplier who will be required to provide tires that are capable of handling more torque sliding. Traction will be crucial.

|

This picture can give you an idea of the size of the Renault F1 ERS-H turbocharger unit |

The loss of power from this reduction in capacity will be recouped in part by the addition of a turbocharger. In this sense, the configuration is not dissimilar to the 1.5-liter turbos used by many teams from 1977 to 1988. Power will also be recouped with a greater use of ERS system. While the systems supply about six seconds of boost per lap for 2013, the new rules will allow the electric assist to be used for 33.3 seconds per lap, significant rise from 2013. Power boost from ERS is now 161bhp from 80bhp in 2013. Maximum harvested energy is raised from 400kJ in 2013 to 2MJ in 2014. Maximum energy that can be used from ES also raised from 400kJ to 4MJ.

In addition to capturing the kinetic energy available during braking, the cars will also be allowed to capture the heat energy that is currently wasted in the engine exhaust.

If you look at the limit on the amount of energy which can be harvested from MGU-K, (2000kJ in a single lap), it becomes clear that the FIA have attempted to add more technical and tactical significance to the old KERS system. No longer it's a simple binary energy recovery and deployment tool likes KERS used to be, which gives a set amount of power for a set amount of time, because the FIA have written into the rules a potential disparity between input and output over a single lap. With this disparity, the use of ERS can become mismatched between two cars racing, and the fact that the minimum time it can be used for has increased also means in theory, ERS will finally have its place in deciding battles between drivers. As you can see there is a lot going on, all of which requires the two MGU's ("K" and "H") to perpetually feed energy around the system so it performs as expected around the entire lap.

|

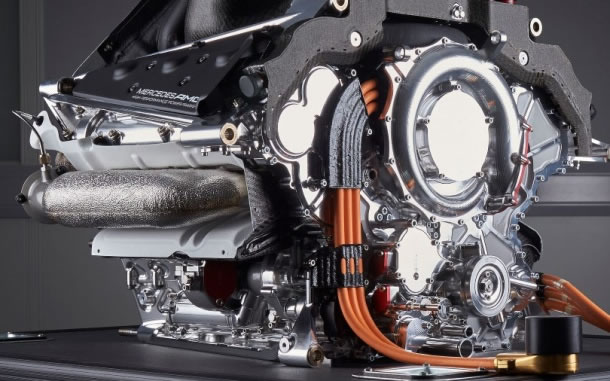

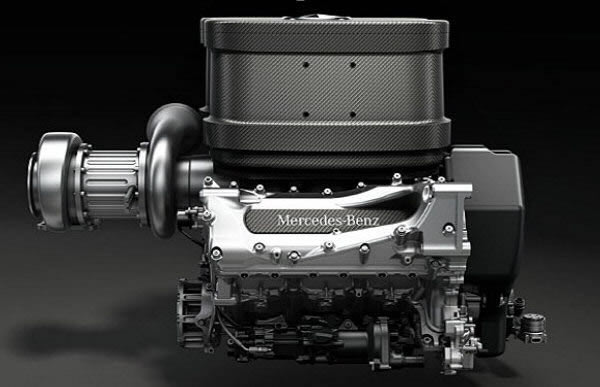

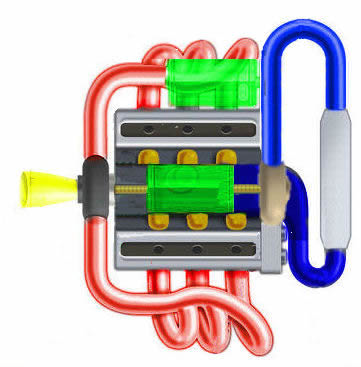

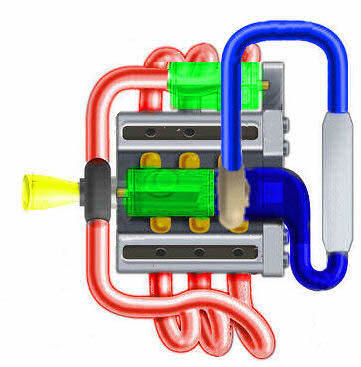

Mercedes team have utterly dominated 2014 Formula 1 season from start to the end wining 16 races. The car was about a second a lap quicker than rest of the grid. Question since the beginning of the season has been why? The big part of the answer is a clever, innovative thinking on the power unit arrangement. A unique design feature of the Mercedes V6 PU106A Hybrid power unit allows it to have specific car design features, the combination of which means it produces more power, more efficiently than the rival engines from Ferrari and Renault. Renault Energy F1-2014power-unit turbine and compressor are located next to each other (upper image). Mercedes (middle image) have split them so the compressor is at the front of the ICE and the turbine at the rear. Ferrari with his Tipo 059/3 power unit (lover image) had the same idea as Mercedes, and their compressor is also detached from the turbine. But the Italian team did not go as far as Mercedes in concept. Their compressor is only about a third of the way or so across the 'v' of the ICE from the turbine, rather than on the other side. Why Mercedes concept is a better idea? Mercedes way has a several benefits. One of the fundamental requirements of a turbocharged engine is to reduce the temperature of the charge air. Remember, cooler the inlet air = more power. |

|

|

|

|

|

So, you have to learn few new words or abbreviation if you like. PU, ICE, ERS-K, ERS-H, MGU-K, MGU-H and ES are a new words you can play around in local pub. The regulations refer to the two devices as the 'Motor Generator Unit – Kinetic' (MGU-K) and 'Motor Generator Unit – Heat' (MGU-H).

|

"Magneti-Marelli Motorsport" Motor Generator Unit – Kinetic (MGU-K) with electronic control unit |

The hybrid KERS-like system is back, but it's been renamed ERS-K (for Energy Recovery System-Kinetic) and the electric motor is twice as powerful, with a peak output of 161 horsepower. 'Motor Generator Unit – Kinetic' (MGU-K) is part of ERS-K which harvest the energy during the braking (as generator), and deliver additional power during acceleration (as motor) to the rear axle. MGU-K must be linked to crankshaft, must run at fixed speed ratio relative to it at maximum of 50,000 rpm. Maximum allowed torque is 200 Nm and maximum power 120 kW (161 bhp).

|

"Magneti-Marelli Motorsport" Motor Generator Unit – Heat (MGU-H) |

PU is easy, Power Unit. It consist of all other parts as ICE, ERS-K, ERS-H, MGU-K, MGU-H and ES.

ICE is old good Internal Combustion Engine, a thing we used before to call engine and is now only a part of PU, as simple as that.

The real novelty, though, is the addition of a second electric motor/generator unit, MGU-H, connected to the turbocharger turbine. 'Motor Generator Unit – Heat' (MGU-H) is part of ERS-H which is mounted on the shaft of the turbocharger and harvest otherwise wasted thermal energy (usually eliminated via a 'waste gate') to be recovered and converted into electricity. BTW, wastegate is still there doing what it always did - expel extra exhaust energy, if there is any.

|

"Magneti-Marelli Motorsport" 2014 ERS-K Energy Recovery System, turbo - MGU-H - compressor assembly used by Ferrari engines |

Known as ERS-H (Energy Recovery System-Heat), this electric unit both captures energy and occasionally feeds it back to the turbocharger to keep the compressor on boost. Why is this useful? Turbochargers have always offered efficiency gains, but these gains come with a price. Because it takes a certain amount of time to spin up a turbine to full speed when it is needed, the turbocharger does not deliver the instant power that is required when a driver puts his foot down. Lots of different tricks have been used over the years to try to reduce the so called "turbo lag" that prevents a turbocharged engine from delivering rapid power changes. I think the most challenging thing for these engines next year is taking the lag out of the turbo. MGU-H can solve this problem by linking the turbo to an electric motor/generator. With this solution, the electric motor can rapidly spin up the turbo when instant power is required. Similarly, when the turbo has more energy than it need, rather than vent excess exhaust through a wastegate, the hot gasses spin the turbine to drive the linked generator unit, which then sends electricity to be stored in the batteries or capacitors when it can be used later on, or directy to MGU-K for instant power boost. Regulation revisions introduced in December 2012 limit the turbocharger to a maximum speed of 125,000 rpm. MGU-H must be mechanically linked to the exhaust turbine, and must run at a fixed speed ratio relative to it. It may be clutched. No variable turbo-supercharger geometry is allowed.

Electricity produced by ERS-H can be used either to power the wheels via the ERS-K motor or to spin the turbocharger compressor. By spinning the compressor during braking, turbo lag can be eliminated or reduced. Although proposed many times at a theoretical level, this elegant engineering solution has never been pursued in a real application. It is a difficult challenge, and it is exactly the sort of technological problem that Formula 1 is good at solving. The turbo unit will spin about 125,000 times per minute, and we can expect that MGU-H motor will run at similar speed. So, ERS-H recovery is done either when the driver is backing off the throttle or when the pressure being produced supersedes the engines requirements. In either case that energy can then either be sent to the ES (Energy Storage / Batteries) or symbiotically shared with the MGU-K via the MGU control unit. Furthermore, there is no limit to the amount of energy which the ES can put into the MGU-H, unlike the MGU-K.

The ES (Energy Storage) can hold up to 4MJ of energy (10 times the current KERS battery capacity) which can be be utilized either by the MGU-H to spin the compressor (reducing lag) or by the MGU-K at a rate of up to 120kw (roughly 160hp). As I mentioned earlier if this 4MJ of energy were to be dispensed solely by the MGU-K at 120kw it would equate to 33.33 seconds of peak power used all in ones with highest settings (120kw/160bhp), but 120kw doesn't have to be dispensed all the time and can instead by used gradually to match the performance of the engine. However we can also see from the technical regulations that the MGU-H and MGU-K share a symbiotic relationship so energy recovered by one source can be dispensed by the other without the need to send it to the ES. It would be possible to recover energy from the MGU-K during braking and release it simultaneously through the MGU-H giving instantaneous power when the driver returns to the throttle without the need of exceeding the 4MJ storage limit. The battery pack must weigh between 20 and 25kg and must be contained in single pack. This means it will be necessary to place the battery pack inside and below the fuel cell, and below the driver, ut must be inside monocoque.

From Ferrari's point of view they've opted (since 2014) to run what is known as a twin battery arrangement, but recently, having made large strides up the grid, the team have seen everything they do put under the microscope. Physically the batteryes are still in one pack as required by the rules, but it's my understanding that it's viewed as two 'virtual' batteries by the software, potentially improving energy and heat management between it and the two MGU's.

|

ERS energy flow chart. For manufacturers a lot to play with. Smarter engineer will, on the end, win the race for best power unit and best power management strategy. The engine is back into Formula 1! |

What makes this interesting for engines is that there is flexibility in the rules as to how these two systems interact and are used harvesting and releasing energy. This will mean different manufacturers could choose different strategies to optimize their units and this will lead to very different engine behaviors. ERS-H will charge the batteries but it will also be able to spool the turbo and finding the sweet spot in that given rule box will be crucial.

The issue that has perhaps led fans to the assumption that drivers only have 4MJ of energy at their disposal per lap is the SoC (State of Charge) statement relating to energy in and out of the battery pack (ES) per lap: "The difference between the maximum and minimum state of charge of the ES may not exceed 4MJ at any time the car is on track". This means that what is limited is only amount of energy passing through the ES per lap. Energy passing directly from MGUH to MGUK and oposite direction is not calculated and is infact unlimited and free to use.

That means that although the MGUK is being fed 120kw it could be getting 60kw from the ES and 60kw from the MGUH (or 40/80kw, or any other ratio for that matter). The more energy that can instantaneously be transferred from MGUH to the MGUK - the better, as this extends the depletion ratio of 120kw from the ES, extending the generally accepted 4MJ figures.

ES will be taken care of by a battery or supercapacitor unit of prescribed weight. Battery Storage is a huge challenge in the ERS system because it must be able to provide storage and be able to deliver high quantity of electricity at rapid rates. The KERS systems in use since 2009 are only required to store 400KJ's of energy which is 10 times less than the new ES. This will require planning in order to achieve the right balance between storage capacity and charge/discharge rates. It's widely regarded that the current ERS battery are made of Lithium Ion cells, but Lithium Ion Polymer cells may give another option in 2014 due to their quicker charge rates and easier packaging. Other option can be use of supercapacitors alone or together with batteries. Problem with capacitors is that they take a lot of space. They are good for short strong pulses. Additional complication with capacitors is that as they discharge, voltage change from high to low very quickly, while battery is easier to control from this point of view.

The issue here is that once a power unit is used during a race weekend, the changes, being tokens or reliability updates, are locked in. Until the car got fired up in the garage, the team actually did not spend tokens at all and could theoretically have kept updating its tokens until the point the car is fired up.

The downside however is quite massive. Each power unit is separated into 6 components, and for 2015 only 4 allocations of each component may be used during the season, before team been penalized. This means an unreliable power unit, like the Renault or Honda are very heavily punished.

So, ones fired, a particular power unit with his 6 components will be locked in its spec, meaning that from that point forward, you are not allowed to replace its core parts whatsoever, no matter if the changes are tokens or reliability updates. The only way to introduce them is introducing another allocation of power unit parts on which the changes apply.

Getting everything working together is extremely difficult to achieve, and having to do so within the tight packaging constraints of a modern F1 car makes it even tougher. These new F1 turbo engines are incredibly complex pieces of machinery, with the recovery of energy by their two electric motors an integral part of their performance. Making sure the cars are reliable all the time will not be easy. In the past few seasons, Kers-system failures happened quite often. But because KERS had such a limited influence on the overall performance, it had relatively little effect on races. But that will not be the case anymore. The influence of these 'hybrid' aspects of the engines has increased enormously - they are 10 times more powerful than they were last year. So an ERS failure will be a major performance disadvantage, and a team won't be able to run competitively and let alone win a race if that happens.

Making sure the cars are reliable all the time will not be easy. In the past few seasons, Kers-system failures happened quite often. But because KERS had such a limited influence on the overall performance, it had relatively little effect on races. But that will not be the case anymore. The influence of these 'hybrid' aspects of the engines has increased enormously - they are 10 times more powerful than they were last year. So an ERS failure will be a major performance disadvantage, and a team won't be able to run competitively and let alone win a race if that happens.

The CE, the Control Electronics (control only hybrid part of Power Unit and work with ECU) is also in some teams sub-divided into eight different units, and so it becomes another level of complexity.

In 2014 only five changes of the power unit will be allowed, and will have to run to 4000km each (four race distances, assuming the calendar remains at around 19 or 20 races, which interestingly, also makes this engines usable in the Le Mans 24 hours race) compared to today's 8 units or 2000km each (three race distances with some units needing to do four); this brought an interesting challenge to the engineers developing them. Bear I mind that here we are talking about 5 POWER UNITS and not ICE units. The regulations state that only five of the various engine components can be used over the course of the season (ICE, MGU-K, MGU-H, ES, turbocharger and the CE), with the sixth incurring a 10-place penalty. If the team uses its sixth of just one type of component - e.g. ERS, turbo, exhaust or control electronics - the driver is subject to a 10-place penalty. But if the team have to change the whole power unit it will therefore be forced to start from the pits. Before 2014 was only the engine itself which attracts a penalty. I think that's a little bit harsh. FIA's plan is to go further: four engines per driver from 2015 and three from 2018. Should a driver exceed their allocation of power units or use more than one of the parts, a grid or time penalty will be imposed.

|

|

Until 2015, only sensors supplied by Gill Motorsport Systems (on the picture above) could be used. From 2016, a new unit, "FlowSonic Fuel Flow Sensor" designed by Sentronics Limited, will be available to all engine suppliers. |

|

The flow restriction is designed to cap engine power - without it, teams would be free to burn lots of fuel at certain points of the lap while still adhering to the race-fuel limit of 100 liters rate - say 150kg/h at the beginning of the race, and 50kg/h at the end of the race, for an average of 100kg/h. With turbo engine you have to limit the power otherwise you would have drivers using over 1,000hp at times, while others were fuel saving. The speed differential would be enormous and dangerous. And that makes it a safety issue, or at the very least a potential safety issue. This also applies to qualifying, where teams would otherwise be able to use specific engine maps that would not have to adhere to the race fuel limit.

The FIA takes steps to ensure that the sensors are accurate and the same for all teams. Team gives its sensors and a sample of it’s fuel to the FIA and they contract a company called Calibra to calibrate the sensors to the fuel, by placing them in series and checking each against a known reference sensor. This is carried out in various conditions and at five different temperatures.

Fuel limitation raised a few question of implementation of fuel restrictors between F1 teams and engine manufacturers. The technical regulation for the power unit fuel mass flow is clearly stated in articles 5.1.5 and 5.1.5 which set a max fuel mass flow rate of 100kg/h at, and above, 10500rpm with this maximum reducing as the rpm decreases in line with the formula outlined in Technical regulations, article 5.1.5. This is a measure of the amount of fuel flowing into the engine at any given point in time. These are maximum values and running more fuel flow than the 100kg/hr restriction provides an obvious power benefit, and any team doing so - intentionally or by accident - is in clear contravention of the rules. Some engine manufacturers believe that restricting the fuel rate is not a right route to take. Some reports say that they are struggling with implementation of its fuel mass flow meters. The challenge has been to ensure these sensors are both accurate and reliable, with several teams complaining of deficiencies and discrepancies between the sensor's rate and what their own fuel-flow estimation was. The flow rate is monitored by the new contactless ultrasonic sensor which weigh 300g and are smaller than a mobile telephone, supplied by FIA certified supplier Gill Sensors (picture above), and reliability of this sensor is key, as the ultimate performance of the car depends on it. They will resolve the problem on the end, but all this additional engineering lead to raising the cost of the units. Typically in racing, air restrictors are used to limit performance. If fuel is regulated in the same way (with restrictors) by narrowing down the flow rate, the fuel may vaporize and cause uneven fuel delivery which can lead to misfires under full power, which can in race condition lead to sudden loss of speed and rear end collisions.

|

The best engine during 2014 season, Mercedes V6 PU106A Hybrid power unit |

Given the struggles of Renault and Honda in their attempts to play catch up with Mercedes and Ferrari, the FIA has altered the figures of available tokens trough the year. It means the areas that were due to be closed off for development in 2016 will remain open, namely the upper/lower crankcase, valve drive, crankshaft, air-valve system and ancillaries drive. Originaly, for the introduction of 1.6-litre V6 turbo-charged hybrid systems last year, the FIA opted for a sharply declining development curve and number of availible tokens. In 2015, 32 tokens were available. For season 2016 FIA and WMSC decided that there will again be 32. For 2017 and beyond, all manufacturer agree to abandon token system. All development into the key areas of efficiency will continue in parallel with the racing programmes. This means that any manufacturer has the possibility to make significant gains from year to year. No one is locked into a situation where they cannot introduce a good idea because they are restricted.

It’s good news for Honda and Renault, who have the most ground to make up and it means that the next two seasons could lead to less predictable patterns as manufacturers can potentially make big steps. I don't know about money savings!

That should open up possibilities for struggling engine manufacturers to close in on the field leading Mercedes.

However Appendix 4 of the F1 sporting regulations allows modifications for "reliability, safety or cost-saving reasons". That relates to the ICE and all ancillaries like the ERS-K and the ERS-H. Which means that manufacturers will probably make the most expensive 1.6 litre V6 turbo they can, so that any new feature can be presented as "cost saving" and not as "performance improvement". Given that F1 technicians excel in pushing rules as far as they can go, you can imagine that after that day Mercedes, Ferrari and especially Renault will be making a lot of "cost savings". And its fairly predictable that engines are also going to get safer and safer as the season goes on.

To explain tokens. Each part of the power unit has been given a certain number of points (tokens). Teams are allowed to “spend” a decreasing number of points from year to year, giving them the opportunity to make some changes with a view to improving their engines without allowing them to make radical overhauls from year to year. Looked at this points as a percentage, eight percent of the power unit's total weight in components have been frozen in 2015, increasing to 23 percent in 2016 or, manufacturers will be able to change 48% of 45 engine components at the end of the current campaign. It may not be much in terms of wiggle-room, but the existing rules do give the engine manufacturers a little bit of breathing room.

And the reasons for these restrictions is cost control.

The price of the current 1.6-litre V6 turbo-charged system is around €20million +, compared to around €8million for the old V8.

And while everyone is focused on the power unit, there are a lot of other things to do there – cooling will be a huge problem that will give a headache to lot of them.

Old KERS has required specific electronic control hardware cooling, and with the bigger ERS the requirement for supporting systems is growing. At the core of the ERS electronics is a control unit, which controls the power inverter and battery management. Unlike the other ERS components it manages, the controller is simply air-cooled and mounted either in the sidepod or in a complete ERS-pod in the fuel tank area. There are a huge number of other smaller electronic units supporting ERS and complet system has more than 30 individual electronic units, all requiring air cooling.

Cooling itself is not a big deal, it's easy to come up with a solution that will cool the system, but to come up with a solution which must accommodate the heat rejection needs of both a turbo-supercharged internal combustion engine and two energy recovery systems, that will cool and give you the optimum aerodynamic performance with minimal drag penalty is the challenge.

Modern racecars still rely on water-to-air coolers to remove heat from the engine, and oil-to-air coolers for the lubricating fluids. Oil cooling of electric motor/generators and batteries is also becoming more common. These coolers are mounted in the sidepods of a car, and the primary concern when specifying these systems is ensuring that sufficient cooling capacity is available to keep the powertrain operating comfortably under race conditions. There is a constant trade-off between aerodynamic drag and engine performance, with a 5°C increase in engine temperature reducing the power output by about 1 hp, with Formula One motors transferring anywhere up to 230 kW of heat into the coolant.

Till now we have an oil cooler, water cooler, gearbox and hydraulic fluid cooler and small KERS cooler. Now you have to add to all of that a bigger ERS cooling water/oil cooler and a big intercooler (charged air cooler). Intercooler for cooling the air from the turbo before it goes into the engine, will, on all of the installations, be quite significant. Physically, the size of the thing will dictate the packaging of everybody's cooling systems and will have big influence of the overall car design, and trying to integrate that much stuff into the car in a neat package is quite challenging. I think it will be interesting and there will be some dramatic differences in cars. Because the different manufacturers are all likely to find individual and diffwrent cooling solutions, 2014 cars can look radically different from team to team.

Energy management is a huge challenge. The most ingenious engineer will win out, and formula 1 will also become a thinking driver's championship to get the most from the car, available energy and how and when to use it.

From 2015, Honda join the grid as a engine supplyer. Honda power unit is likely to be slightly behind in its first season, that is the general oppinion among engineers. However one major advantage it has over its rivals when building a first generation hybrid turbo engine is that it knows what the performance benchmark is, namely where the other rivals’ power units are at the moment. Speak to any engine builder and they will tell you that "knowing the target" is worth a lot to the R&D engineers. When Mercedes, Renault and Ferrari were building their engines for 2014 none had any idea what the performance level of the best one would be, it was a shot in the dark.

From 2015, Honda join the grid as a engine supplyer. Honda power unit is likely to be slightly behind in its first season, that is the general oppinion among engineers. However one major advantage it has over its rivals when building a first generation hybrid turbo engine is that it knows what the performance benchmark is, namely where the other rivals’ power units are at the moment. Speak to any engine builder and they will tell you that "knowing the target" is worth a lot to the R&D engineers. When Mercedes, Renault and Ferrari were building their engines for 2014 none had any idea what the performance level of the best one would be, it was a shot in the dark.

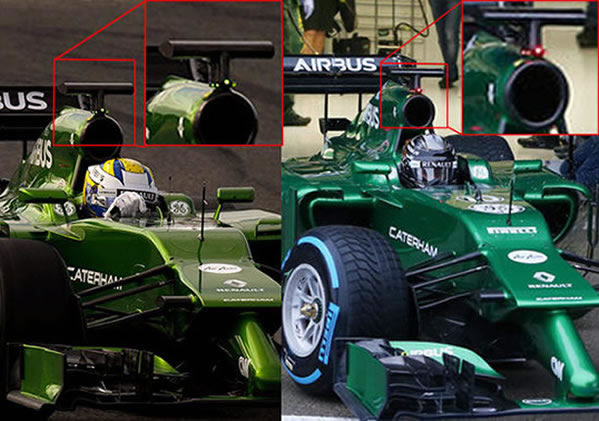

To prevent accidents like one in Williams pit lane during testing 2008, explained in KERS article, FIA issued new rule for 2014, more powerful ERS system. From 2014, all cars must be equipped with red and green signal light on the rollhoop below upper camera pod. When ERS is armed and car is unsafe to touch LED light is red, and when car is safe to touch light change to green. You can see how it looks like on Caterham CT05, pictures taken during preseason Jerez test in February 2014.

And of course we must not forget a significant aerodynamic change. It may not sound much - moving the front wing in a little bit, lover noses, losing the beam wing at the rear wing assembly and small changes like that - but in fact that aerodynamics of today cars are so interrelated that it really is something you need to think about a lot.

Drivers will have a huge challenge to fight torque delivered to rear wheels. In 2014 we will have much lower revs than the old engine. Next year they'll max out at 15,000rpm, but a lot of talk is that they'll only have usable revs of up to around 12-13,000rpm for the sake of drivability. This increase in torque will make for great viewing as the drivers try to handle extra low end power. I think the low revs, combined with braking into a corner will be key. I think that this will be the big difference in driving styles between 2013 and 2014 - getting the car to balance and stick in corners that you'll be looking to take at around 120-150mph. Different torque patterns mean that they will gain and lose grip at different times to the current naturally aspirated engines because the turbo will provide a lot more power and torque to the rear wheels a lot earlier. This will make the cars harder to keep on the road when accelerating out of a corner (remember that modern F1 cars don't have traction control). That means the car is going to be grip limited, in technical terms; in layman's terms, they're going to be a handful for the drivers.

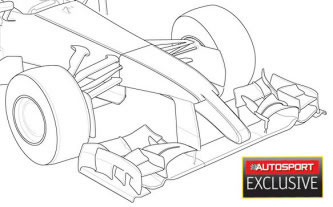

Formula 1 technology journalist\illustrator Craig Scarborough on his blog scarbsf1.com, writing for autosport.com this article, raised a question of possible ugly nose designs provoked by the new rules that ask for high chassis of 525mm and a low nose tip at 185mm. The chassis shape is defined by three points - the bulkhead at the front of the cockpit opening, which has a maximum height of 625mm above the floor of the car; the bulkhead at the driver's feet, which has a maximum height of 525mm; and the crash structure in the nose, which is approximately one metre forward of that. That area has been lowered to 185mm - that's 365mm lower than in 2013, and a low nose tip now at maximum height of 185mm.

Formula 1 technology journalist\illustrator Craig Scarborough on his blog scarbsf1.com, writing for autosport.com this article, raised a question of possible ugly nose designs provoked by the new rules that ask for high chassis of 525mm and a low nose tip at 185mm. The chassis shape is defined by three points - the bulkhead at the front of the cockpit opening, which has a maximum height of 625mm above the floor of the car; the bulkhead at the driver's feet, which has a maximum height of 525mm; and the crash structure in the nose, which is approximately one metre forward of that. That area has been lowered to 185mm - that's 365mm lower than in 2013, and a low nose tip now at maximum height of 185mm.

Regulation also demand a relatively small nose tip cross-section, and teams will want to minimise the width of this area to improve air flow under the chassis. This can lead to narrow, drooping nose to meet minimum cross-section requirements, protruding from a higher, more bulky, section that will pass crash tests and fit teams aerodynamic needs. It is understood that several leading outfits will go this route. AUTOSPORT understands that some senior Formula 1 technical personnel have already called for changes to improve aesthetics, but this was not successful due to a lack of agreement on the need to do something. Red Bull design chief Adrian Newey and McLaren sporting director Sam Michael have admitted that the 2014 cars are likely to be "ugly" due to the front impact structure. Follow this link to check my article about new 2014 nose cone rule and designs.

Other big difference will be braking behavior, and that is harder to predict. As we've seen a lot in the last few years, old KERS recovery does weird things to the behavior of the car under braking because it affects the brake balance, brake bias and rear axle. However, KERS was very much bolted on to pre 2014 cars, where as in 2014 it is completely integrated in the power unit. Because of this, we don't know how they'll affect the cars under braking. That's why FIA tech regulations introduce for 2014 new rule which allow teams to use electronic brake assistance on rear wheels, so called brake-by-wire system. This has become necessary due to the significantly increased harvesting performance of the ERS, which requires much greater variations in rear wheel braking torque than previously. With brake-by-wire, an electronic system measures how hard the driver presses the brake pedal and then – using the additional information from energy recuperation – assess in a split-second how much brake pressure the driver has called for when he presses the pedal and an electronic system modulates the power to the rear brakes, allowing for the ERS effect, that is taking energy to charge up the kinetic motor generator unit. It smooths out the process, slowing the car in a consistent way at the same time as ensuring the maximum energy harvest for the ERS. In other words, because the ERS (Energy Recovery System) is so much more powerful on these new cars compared to the KERS on the 2013 cars, harvesting energy when the car is braking – 161bhp of energy compared to 80bhp with the KERS – it is essential that the engineers install a system to compensate for the powerful effect that has on brake balance and braking stability. This makes it acceptable for the driver and doesn’t destabilise the car with a sudden balance shift. A lot of the lap time in modern F1 comes from stable braking.

The next point is that it will reward the most intelligent drivers - the fastest way to finish a race will not always be straightforward and the smartest drivers will probably adapt fastest to the new challenges. Managing fuel consumption is already a critical part of F1 and it will remain more so in 2014. But already before 2014, teams are very good at monitoring fuel consumption. They track each injection of fuel into each cylinder so they know exactly how much fuel is being used. And there are over five million injections in an average race!

But overall, it's about putting the engine back into motor sport. It will very much be an engine formula - especially at the beginning. They've taken a lot of power out of the aerodynamics and there is a lot more emphasis on how effectively and how efficiently you can use your various energy sources. That was the intention and that will happen.

We can expect more spectacular racing, with F1 cars having more power than grip on corner exits and an opportunity to showcase technology and innovation, putting F1 back at the cutting edge of the motorsport. I think that improved ERS will almost definitely benefit the sport, both in image and in racing terms. The scope for tactical games within different systems is unmatched in F1 history. By simplifying car design and limiting the areas which can have aero parts, it is far more likely that teams will focus on the development of the renewable energy system, allowing F1 to claim once again that it is at the forefront of technology and innovation. And ultimately, the smartest driver in the quickest car will be successful in 2014, which remains true to the fundamental challenge of Formula One.

I think, initially, there will be maybe a surprise results because reliability will be a very poor at the first few races. You may well have a car that is not very fast but keeps going, and you have a winner of the race. So we might see a big surprise results.

Also, while you're not going to run out of fuel with these cars as they're too closely monitored for that, but you might find the pace drops off dramatically at the end of races - a lot more dramatically than before. So the closing stages of races are probably going to be very exciting.

After first race of the year in Australia, there where a lot of comments, particularly on the sound. I am torn on this. In some ways quieter cars are better for everyone, speaking as one of the thousands of people whose hearing was damaged by being too close too often. Comparisons with lawn mowers were common, while one fan asked whether the new engines are "powered by farts". Others commented that it was nice to be able to discuss with friends and family what was going on around them, and to be able to hear that PA system and other noises. I think there are always going to be people who have negative observations because some people simply get stuck in the mud. That is inevitable. There is no doubt that something has been lost. Like every big change, there are always pros and cons. But, as someone pointed out to me, what's the point in very loud engines when you then need to put earplugs or your fingers in your ears which can ring for days afterwards? The truth is that very quickly fans will get used to the new noise and no-one will even notice it in a few races from now. This is in human nature. For some fans (not technically educated as as) noise equals power, even if in reality that is not the case. New engines will not sing like the old V8s, but people forget that before the V8s we were used to the melodies of orchestras of V12s. Things change.

The sheer roaring, wildness of the V8's was enough to send a shiver through your spine every time. The old cars physically invaded your space as they approached, hammering the ground. Today sound is different, but not that different from the turbo engines we had in the 70's/80's. Anyhow, the pinnacle of motor sport felt just right being ludicrously loud. But our sport is still a magic thing and a few missing decibels will not change that. We have to understand that with a turbocharged engine there is far less energy being pumped out of the tailpipe. Therefore there is far less sound. And sound is energy. I think you should always remember that the increase in sound is just loss of power and I think that when you’re harnessing all the power available and it means that the engines are quieter then you’re actually doing a more efficient job. Unburnt fuel spiting flames out of exhaust pipe and noise sent down the exhaust pipe is simply wasted energy. Nice to see but waste of energy. I think that it would be very disappointing if we’re just judging Formula One purely on the fact that it makes a lot of noise.

Yes, Formula One's volume has been turned down over the winter, there is no doubt about that, but until you've heard the fascinating multi-faceted engine noise from trackside it's worth reserving your judgement.

You can't hear scream of the engines as before, but in its place are several more interesting sounds. From trackside in a braking area you'd hear cars locking their wheels up, the whistle and whine of turbo and cam gears, the engine note, the rumble of resistance as torque was taken from the rear axle and fed to the battery, the gear changes, the screech of lock-ups, sqeeling of brakes, whizzes, groans and pops. It was the low volume that made it possible to distinguish the various phases as they flashed by at enormous speed on the straight - visibly quicker than the V8 cars - the mixture of mechanical, turbo and electrical sound (In Melbourne cars are about three seconds a lap slower then 2013 (1:29.375 vs. 1:25.908), but in terms of outright speed they are actually travelling faster in a straight line than before. The fastest time recorded through the speed trap from the race was 316.9kph (McLaren's Kevin Magnussen), last year speed trap 303 km/h) which was quicker than anything seen during the eight-year V8 era, less downforce = less drag). Rosberg's pole position time in Bahrain was only 0.8secs slower than last year, despite heavier cars, reduced aerodynamic downforce and a fuel restriction. On the straight in Barcelona, the fastest car was doing 347kph compared to 318 last year, but pole positionwas 4.5 seconds slower than last year. What was most significant, if the chequered flag had not waved a lap too early, Lewis Hamilton’s race time over 56 laps in Shanghai would have been 1h36m52.810s. Compare that to last year and the year before and you will see that the race took about 26 seconds longer than it did in 2013 and 2012. Not even half a minute. In percentage terms, therefore, there was a loss of less than half a percent in terms of performance. Using around 33 percent less fuel. And I’m willing to bet that by the end of the year, the races will be run even faster than they were 12 months ago.

Each engine sounds noticeably different, with the Mercedes offering a guttural roar and the Ferrari singing some more tuneful high notes. But even if the aural appeal has been muted, the cars are much more fun to watch, with the torque of the engine often overwhelming the grip of the rear tires. For casual TV audiences, that should eventually make up for the loss of noise. And for us, real fans, we will get used to it and love it. The combination of the big rule changes, the new sounds and technology and the new driver talent on show, return of the skill back to the cockpit, plus the complex challenge of managing fuel loads made for a real sit-up-and-take-notice season. The cars are powerful, unruly and unbelievably complex and they are proving a handful for the world’s top drivers. No doubt things will settle down and the drivers and teams will gradually learn, but in the meantime it looks like we could be in for some exciting racing in the early part of the season.

So I’m very pro this new Formula 1 and the challenges that it’s given to the teams. I think that it’s great that we’re seeing cars that are difficult to drive, that are on the limit, that are breaking away at the rear end, which is something that we’we not done for a long, long time. For an engine to deliver similar power to last year, with more than 30 percent less fuel consumption I think is just an incredible achievement. Also what is important is that Honda is coming back next year and it’s the first time we’ve had another major motor manufacturer coming back into Formula One for a long time.

24th March 2014, FIA President Jean Todt made, during an interview with Italian national broadcaster Rai following statement:

"The noise is obviously different now and if there is a problem with it we can look at a way to make it noisier."..."I do not want F1 "economy runs", the permitted amount of fuel, 100kg, was proposed by the teams. For me it is not a problem if they want it to be 150kg,"

So, as usual, Formula 1 is shooting himself in the foot with ongoing failure to publicise amazing current technical revolution, to promote the ferocious brains who have made this new era possible.

If we are talking already about 2014 rule change, let's see this changes and compare them with 2013 formula 1 rules.

- In 2014 engine changed name in "power unit" and they are be 1.6 litre V6 boosted with a turbocharger and greater energy recovery systems. They can boost around 600HP (without ERS, prediction for the beginning of the season) at up to 15,000rpm. The power unit is fuel flow restricted. They have new direct injection into cylinders, with fuel pressure at 500 bars. Teams have just five power units/car/season and each has to last 4000km.

In 2013 the engines were 2.4 litre V8s with fuel indirect injection. In 2013 engines produced around 750HP at up to 18,000rpm. 2013 teams had eight engines/season/car and engine units had to last 2000kms. - In 2014 gearboxes have eight forward gear ratios plus reverse gear. Each team must nominate all ratios ahead of the season.

In 2013 gearboxes had seven gear ratios plus reverse gear. - In 2014 teams have to manage with total load of 100kg of fuel, and fuel flow is restricted to 100 l/hour at more then 12.000RPM-s.

In 2013 teams weren't limited to a fuel weight or flow, though typically they'd have 160kg on board at start of the race. -

In 2014New exhaust rule mandate a single tailpipe of fixed dimensions, which must exit 170-185mm behind the rear axle line and 350-500mm above the floor. Circular end of the final 150mm of tailpipe to point upwards at an angle of five degrees. Exhaust can be offset from the car's centre-line by 100mm, which could allow the retention of the monkey seat winglet. Any bodywork in the area behind the tailpipe's axis is also banned, preventing vanes or winglets from diverting the plume towards the rear wing or diffuser.

In 2013 you could have two exhaust pipes on each side of the car which could be directed over the rear bodywork (blowing effect). - In 2014 ERS can harvest energy from two sources - kinetic energy from braking, ERS-K, and heat energy ERS-H fitted on turbocharger. ERS can deliver 160HP and is available for around 30 seconds/lap.

In 2013 KERS energy harvesting was done using only brake energy to drive a generator. Harvested energy was good for around 6-7 seconds a lap delivering 80HP. - In 2014 electronic rear brake control system is allowed to prevent strange behavior of the brakes during harvesting this much energy under braking, compensating for the need for the driver to constantly alter the brake bias.

In 2013 drivers was allowed to adjust the brake bias only manually to change the KERS harvesting. - In 2014 lower rear beam wings below the main rear wing are gone. Rear wing main flap is slightly shallower in profile, because flap area is now reduced from 220 to 200mm. Also position of camera and dummy camera support are tightly regulated.

In 2013 teams used beam wings. Rear wing flap area was 220 mm. Camera and dummy camera support was used for aerodynamic advantage. - In 2014 front wings are narrower with wide of only 1650 mm.

In 2013 were 1800mm wide. - In 2014 for safety reasons (to prevent disastrous t-bone or nose-to-wheel crashes, to reduce the likelihood of cars launching in the air in case of a front to rear impact, and also to reduces the risk of a driver sustaining head injuries, which could happen with the previous higher nose design) nose cone tip height of cars is a much lover at 185mm from reference plane. Height of the forward bulkhead is reduced to 525mm. This will impact aerodynamics as the air flow under the nose and chassis will be obstructed. Also there is a problem of possible ugly design of new noses. Because regulations demand a nose tip cross-section of only 100mm2, teams will want to minimise the width of all nose area to improve air flow under the chassis. That can give a possibilities of slender, drooping nose tip extensions only to meet minimum nose cross-section rule requirements for this section, protruding from a higher, more bulky, section that will pass crash tests and fit teams' aerodynamic needs.

In 2013 the nose height was 550mm from reference plane. Height of the forward bulkhead was 550mm. - In 2014 to compensate for the increased weight of the new power unit with heavy energy recovery systems incorporated, car weight is increased to 690kg.

In 2013 a car weighed 642 kg. - In 2014, following 2013 tire problems, the FIA has inserted a line into the regulations that allows it to change the tire specification without notice or delay.

in 2013 for this decission was necessary to have mayority vote of all F1 teams. - In 2014 a new side impact structure is introduced. Following a project lead by the FIA Institute and the teams, more resistant structure to angled side impacts is developed, which might previously have been torn off.

In 2013 old side impact structure was in use. It was noticed that with strange impact angles structure can be torn off.

Ahead of of its 2014 home race at Japanese Grand Prix in Suzuka, Honda revealed the first image of its 2015 V6 turbo power unit. That will be followed by sneak preview video and audio of the new turbo over the weekend - while the manufacturer revealed McLaren may well run with Honda engines before pre-season testing next year.

Ahead of of its 2014 home race at Japanese Grand Prix in Suzuka, Honda revealed the first image of its 2015 V6 turbo power unit. That will be followed by sneak preview video and audio of the new turbo over the weekend - while the manufacturer revealed McLaren may well run with Honda engines before pre-season testing next year.

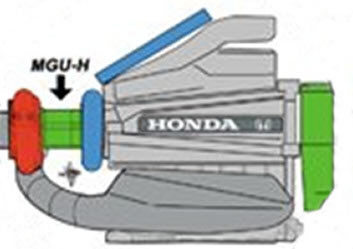

Having quit Formula 1 in 2008 as a works HONDA F1 team, the Japanese manufacturer's name will be back on the grid in 2015 as a power unit supplier for McLaren. The company has revealed very little about its plans or design details so far, but they released the first image of its power plant.

The Honda website gives little detail about the new power unit, although diagrams explaining how the current generation of hybrid engines work shows a conventional layout of the turbocharger in line with Renault and unlike Mercedes' successful split turbine and compressor. However, an actual photo of the engine without engine head cover has not been released so the secrets of the Honda power unit are likely to remain just that until the start of next season. The biggest question-marks: can it come in an immediately challenge Mercedes, Ferrari or Renault power units, and who will be driving the Honda-powered McLaren MH4-30?

Honda motorsport chief Yasuhisa Arai also confirmed that the revamp at their new base in Milton Keynes is done.

The sweeping rule changes of 2014 mean that the current technology in Formula One racing is still relatively new, and that has led to gains being made across the board ahead of the forthcoming 2015 campaign. Teams have refined their bodywork and aerodynamics, while the efficiency and output of power units has come on leaps and bounds. The upshot? Lap times are likely to be a whole lot faster this year.

That was already proved at first test session in Jerez, where Kimi Raikkonen’s test-topping 1m 20.841s was in the region of 2.5 seconds quicker than last year’s corresponding benchmark.

At Barcelona last test before session start, Mercedes sent an ominous message to their rivals by shattering the best time of pre-season testing at the Circuit de Catalunya. Just over an hour from the end of the session Rosberg went out on a soft tire run and crossed the line in 1m22.792s,

2.5s quicker than Lewis Hamilton's pole time from the 2014 Spanish Grand Prix (1m25.232s ), highlighting the progress made since last year. And all this times are made in cold winter wether. Ambient temperatures at Barcelona didn’t get above the teens° centigrade. Pirelli is estimating between two and two and a half seconds per lap improvement.

Australian GP 2014 pole was 1:30.775 – 2015 Lewis’s pole time was 1:26.327 We can expect much more during the year.

About PU high price during Abu Dhaby Yas Marina friday’s November 27 2015 FIA press conference Toto Wolf (Mercedes AMG F1) ansvered:

Q: (Dieter Rencken – Racing Lines) Toto, from the pit lane in Brazil, you seemed to indicate that the difference in price to the teams of the new engine to the old engine is about plus twenty percent which works out at ten percent per annum, or if that price gets held for next year, about six percent per anum, which is roundabout six percent of a smaller team’s budget. What’s the big outcry about, why do you want to throw this engine out with the bathwater when in fact there’s only about a six percent difference from one to the other?

TW: I couldn’t follow you on that calculation. But the main point is that there are lots of numbers out there and lots of wrong numbers out there and as a matter of fact I can only speak for Mercedes because these are the calculations I know, it’s from a previous engine spec: the old eight cylinder engine plus KERS. About the difference to what we have today, it is what you have mentioned, 20 or 25 percent. Is that too much? Maybe. I remember times when I joined Formula One a couple of years ago, the price was around £30m, three-zero plus a driver. Nevertheless, I think it’s legitimate to question the price and obviously the lower the price, the better it is for Formula One, the more sustainable it becomes, the better it is for most of the teams and that is OK and we need to look at it. But the difference is not what’s been said.

In same time, head of Mercedes’ AMG powertrains Andy Cowell explained that being able to use the Electrical Recovery System (ERS) combined with the 1.6 litre engine for a full lap, make the current engines more powerful than the previous V8s. He said:

“If [you] just look at the internal combustion engine, then today’s V6 1.6 litre turbo-charged engine is approximately the same power as the V8 engine was. Both of those ran a hybrid system and if you add the KERS system onto the V8 and the ERS system onto the V6, and look at their maximum power values, then today’s V6 with ERS is 10 per cent more powerful than we had with the V8 and the KERS system. The ERS system is available for the majority of the lap. The KERS system was only available for 6.7 seconds of the lap, so in terms of laptime, impact of the V6 and ERS, is significantly greater than we had with the V8 and KERS system.”

Cowell added that the current V6 power units are now producing more power than the V10 engines, which were last used in F1 in 2005 and hold most of the lap records at circuits still on the calendar from that era, and are almost twice as efficient.

“If you look at the fuel flow rate of the V10 era, it was over 190 - 194kgs an hour, and today we’re at 100kgs an hour. [It’s] the same power, [with] about half the fuel flow rate, which is a phenomenal change in terms of efficiency of the power unit, as we now call it. [It’s been] incredible improvements of efficiency, incredible absolute power levels from this this little, diminutive 1.6 litre internal combustion engine – it’s kicking out an awful lot of power."

Mercedes has dominated Formula One since the introduction of the current regulations in 2014 and for most of that period it has held a significant power advantage over its rivals. In a presentation to media at the team's engine factory in Brixworth, Andy Cowell, Mercedes engine boss explained that the current 1.6-litre V6 turbo hybrid is now producing more power than the 3.0-litre V10 Mercedes engine of 2005, in excess of 900bhp, and says there is no reason to believe its development rate will slow in the next few years.

"It's the most powerful Formula One engine [we've made] with over 900bhp. It's pretty good going from this little nimble 1.6 litre engine, but that power has been created because the efficiency has changed. We've got road-car technologies in there and new emerging technologies are in there with regard to the MGU-H."

Cowell revealed that the Mercedes power unit is now achieving more than 45 percent thermal efficiency -- i.e. 45 percent of the potential energy in the fuel is delivered to the crankshaft -- and efficiency of more than 50 percent when the ERS is operating at full power.

By comparison, the V8 engines pre-2014 achieved thermal efficiency of 29 percent and the first iteration of the Mercedes V6 turbo in 2014 managed 40 percent thermal efficiency.

Back to the top of the page