Wheel Gun & Wheel Nut

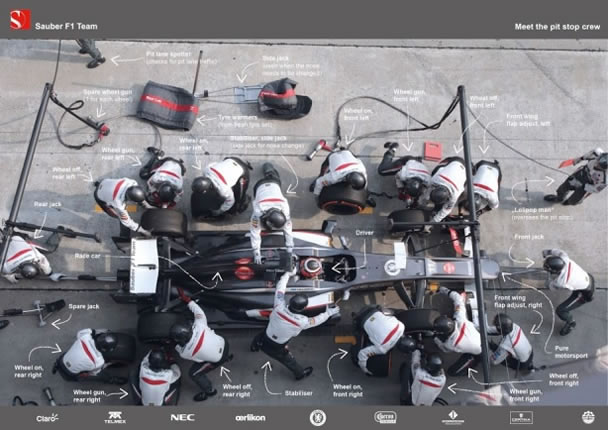

Throughout Formula 1 pitstop history they’ve always played a direct role in the outcome of races and as such, the speed with which they’re completed is crucial.

1984 refueling was banned after few fires during the pitstop. That was not a surprise because teams try to shove as much fuel into their cars as quickly as possible. And back then it was often a form of highly volatile fuel mix, making it perilously dangerous. This brought the focus away from pitstops and into the ability to conserve fuel and tires during a race.

In an effort to spice up the show after a ten year break, 1994 saw the reintroduction of mid-race refueling. Teams very quickly began to look at ways of speeding up their stops once more. Although everyone had to use the same refueling rig, pumping at the same rate of maximum 12 liters per second, the same hose, nozzle and valve in the side of the car, teams tried simple ways to make the operation ultimately faster. Perhaps the most infamous example was the Benetton pitstop fire of the same season. Investigation uncovered that the team had removed a filter in the standard fuel rig, designed to restrict the flow rate of fuel from rig to the car fuel cell. The increased flow rate would mean the required amount of fuel could be pumped into the car faster than their rivals and of course reduce the time spent in pitlane.

With refueling gone once more, pitstops became all about replacing four wheels and tires as fast as possible. Before there was no desperate need to change tires in 3 or less seconds when refueling would take at least another 4, 5 or 6. In days gone by, it wasn’t an uncommon occurrence to see wheel nuts spinning off down pitlane during pitstops or pitstop practice as they popped out of the wheel gun when the wheel was removed. Of course it was hardly ever an issue as a spare nut, always on hand, could be picked up and fitted long before the fuel man had finished his part of the job.

Mechanics of the 50’s and 60’s have to use a hammer to tight a wheel to the wheel hub. Thankfully Formula One’s moved on in every area and tire change technology are no exception. Today’s (2014) world record breaking stops to change four wheels in under 2.5 seconds are impressive to say the least, but they’re the culmination of years and years of development, learning, and improvements in technology.

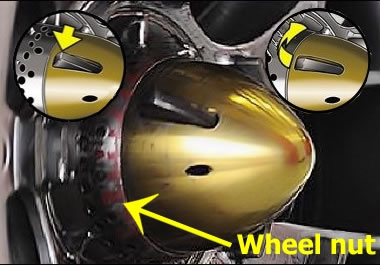

Wheel nut may not be the most glamorous part of a Formula One car, but it still needs to be engineered perfectly if costly pit-stop errors are to be avoided. Like the majority of a Formula One car's parts, the manufacturing of the wheel nut became a particularly scientific process. Wheel nuts are unrecognizable compared to just a few years ago. New ones don't tend to look like wheel nuts at all. They've got all these special sockets and odd-looking fins on them, and are supposed to be more efficient for pit stops.

Wheel nut may not be the most glamorous part of a Formula One car, but it still needs to be engineered perfectly if costly pit-stop errors are to be avoided. Like the majority of a Formula One car's parts, the manufacturing of the wheel nut became a particularly scientific process. Wheel nuts are unrecognizable compared to just a few years ago. New ones don't tend to look like wheel nuts at all. They've got all these special sockets and odd-looking fins on them, and are supposed to be more efficient for pit stops.

| Precisely machined pockets in the wheel nuts ensure the wheel gun positively and fast connects with the nut so that the torque can be transferred reliably to tighten the nut. Each wheel seats precisely on drive pins on the axle. They are positioned in such way to make the wheel fit at first time, without need to be wiggled on the hub. |

|

|

|

Williams Formula 1 team 2013 wheel nut, upper image (click on image for bigger resolution), and on the right, two wheel nuts from R29 and R30 Renault Formula 1 car. Advances are visible. |

|

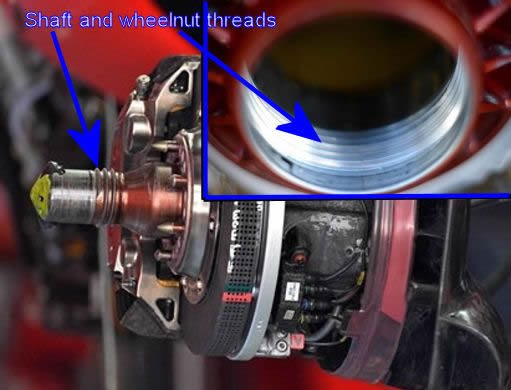

FIA rules demand the nut is retained on the axle by a locking mechanism. This used to be a plunger that when pulled by the mechanic extended retaining pins from the axle. Today nut retention is a spring activated system which does not demand any action by mechanic. On the picture right you can see Ferrari locking system. The wheel gun socket pushes the pins into the axle to allow the nut to be removed. When refitted the nut passes over the pins and they spring out when the nut is nearly fully seated and gun removed. With this system, it's not until the wheel gun socket is pulled from the axle that the mechanic can visually confirm the nut is on and the retention mechanism is in place. Often we see mechanics signal their job is done and then frantically wave amid the realization that the nut is not in fact fitted correctly.

FIA rules demand the nut is retained on the axle by a locking mechanism. This used to be a plunger that when pulled by the mechanic extended retaining pins from the axle. Today nut retention is a spring activated system which does not demand any action by mechanic. On the picture right you can see Ferrari locking system. The wheel gun socket pushes the pins into the axle to allow the nut to be removed. When refitted the nut passes over the pins and they spring out when the nut is nearly fully seated and gun removed. With this system, it's not until the wheel gun socket is pulled from the axle that the mechanic can visually confirm the nut is on and the retention mechanism is in place. Often we see mechanics signal their job is done and then frantically wave amid the realization that the nut is not in fact fitted correctly.

Ferrari has gone first down the route of less threads of engagement for the wheel nut on the shaft, meaning less rotations of the nut meaning less time lost. They are using only 3 threads. Today stub axles on the every car have from 5 to as little as 3 threads, to minimize the number of revolutions it has to do in tightening or releasing the wheel.

Axle tip is rounded to guide the wheel into place. On the picture left you can see rounded axle tip painted red and wheel nut fitted on it.

Axle tip is rounded to guide the wheel into place. On the picture left you can see rounded axle tip painted red and wheel nut fitted on it.

Ferrari and Mercedes have first adopted a "nut on wheel" solution which means the nut floats within the rim itself, a loose fit inside the wheel. This means that the nut is partially located on the axle as the wheel is slided on the it. This saves time for the tire removers/fitters and gun man as there is physically one less job to do.

Wheel nuts themselves are retained within the rims with "O" rings or circlips to reduce the opportunity for cross threading and take away the possibility of one falling out of the wheel gun socket. These expensive spline drive type wheel nuts are normally used just once. Like the stub axles, drive pegs on the car’s uprights and the wheels themselves are designed to guide them seamlessly together and avoid ‘pegging’, where the two butt up against each other and fail to engage.

Wheel nuts themselves are retained within the rims with "O" rings or circlips to reduce the opportunity for cross threading and take away the possibility of one falling out of the wheel gun socket. These expensive spline drive type wheel nuts are normally used just once. Like the stub axles, drive pegs on the car’s uprights and the wheels themselves are designed to guide them seamlessly together and avoid ‘pegging’, where the two butt up against each other and fail to engage.

Biggest enemy of the wheel nut is the pneumatic air gun used at pit stops. The gun will often bend a nut out of shape or destroy the fins, rendering it useless. On the right picture you can see used Mercedes AMG W02 wheel nut (click for bigger resolution).

Biggest enemy of the wheel nut is the pneumatic air gun used at pit stops. The gun will often bend a nut out of shape or destroy the fins, rendering it useless. On the right picture you can see used Mercedes AMG W02 wheel nut (click for bigger resolution).

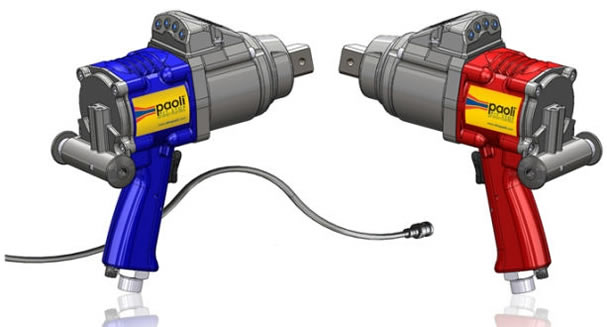

Until 2012, helium was used to drive the wheel guns during pitstops. Using helium to power wheel guns is one of a million technical exercises you’ll find only in Formula One. Like mercury-filled inerters or $20,000 per piece rotary dampers, they are a way to shave another few milliseconds between start and the checkered flag. What helium does is make the wheel guns rotate faster due to its extremely low density, which translates into a faster wheel change, which translates into a faster pitstop, which translates into a faster race.

Formula One’s wheel guns with a high flow and hammer effect are quite amazing pieces of highly specialized machinery. Made by the "Dino Paoli" company in Italy, they produce over 3,000 Newton-meter of torque. just as comparison, good modern diesel car can pull 300 - 400 Newton-meter of torque. "Dino Paoli" supplies almost all teams, but I believe that McLaren develop their own guns. Wheel gun men now use custom made guns, customized by the team or by "Paoli". ‘High flow’ gun allow greater air flow through the gun itself and effectively spin the socket faster, around 9000 rpm.

Formula One’s wheel guns with a high flow and hammer effect are quite amazing pieces of highly specialized machinery. Made by the "Dino Paoli" company in Italy, they produce over 3,000 Newton-meter of torque. just as comparison, good modern diesel car can pull 300 - 400 Newton-meter of torque. "Dino Paoli" supplies almost all teams, but I believe that McLaren develop their own guns. Wheel gun men now use custom made guns, customized by the team or by "Paoli". ‘High flow’ gun allow greater air flow through the gun itself and effectively spin the socket faster, around 9000 rpm.

Each corner of the car gets two wheel guns, with the second there in case the first one fails. Although problems such as faulty guns are rehearsed by the pit crew, everyone focuses on their own job. In a two-second pitstop, there is no time to see what everyone else is doing. Guns will have bespoke grips, with abrasive paper or grippy silicone. Strong hands are needed to operate these beasts.

Each corner of the car gets two wheel guns, with the second there in case the first one fails. Although problems such as faulty guns are rehearsed by the pit crew, everyone focuses on their own job. In a two-second pitstop, there is no time to see what everyone else is doing. Guns will have bespoke grips, with abrasive paper or grippy silicone. Strong hands are needed to operate these beasts.

|

|

|

|

The guns of today have bespoke sockets to match the team’s own nut designs, lights to indicate to the mechanic when the nut’s done up to the correct torque and buttons to signify to the jack man that the operation’s complete. Before the recent focus on pitstop speed, gun men would give a sign when they were done by raising a hand in the air and when the jack men saw the two hands at their end of the car, car would be lowered back onto the floor. When the chief mechanic saw four hands and both jacks out of the way, he would release the car. Now, the action of raising a hand 50cm in the air is considered to take too long, so a button is fitted on the wheel gun. The flick of a switch or button on the side of the gun shaves off valuable hundredths. That’s how thoroughly things are analyzed. A raised hand is still in use as the back-up to this electronic method. Always mechanic first flip the switch and then rise the hand.

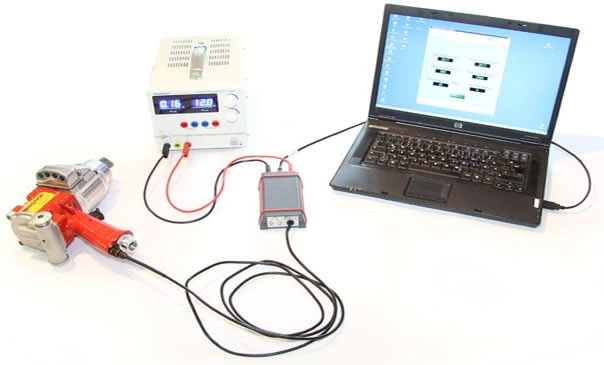

Gun is also fitted with a torque sensor. This sensor will record what the tightening torque was. This information can be reviewed later if needed. As the rules currently stand, this sensor cannot be used in real time to confirm to the pit crew that the correct torque was achieved.

|

"Dino Paoli" wheel gun, model DP4000MG with Palindrome Sport "NUGUN Back" Nugun quickShift fitted |

The gun is quickly reversible. To change direction of rotation, gun has a switch on the back side, and you can see during the pitstop that mechanic hit his chest with the back side of the gun or a giving a firm punch with the palm of the hand after removing used tire (clockwise rotation). This action change position of the switch and with this direction of rotation, to prepare a gun to fit new tire (counter clockwise rotation of the gun).

One of the very latest developments in wheel gun technology is an automatic direction change. Nugun (ex Rhodri Griffiths), the man credited with most advances in F1 wheel gun technology, has devised a new system, the Nugun quickShift, which switches direction automatically as the gun is removed from the first wheel. This is actually auto-reverse gun back side only, to suit Paoli's high-performance wheel gun range.

Ferrari customized "Paoli" wheel gun, a standard item customised to be super powerful and with buttons to confirm the wheel change is complete

During the pit stop every tenth of the second counts. Before, few years ago, pit stop time was depending on to many people reaction. After wheel nut is tightened, wheel gun boy will raise the hand to give the signal that he is OK (tight the wheel nut, remove the gun from the nut, raise the hand). When front and rear mechanics on the jack see that all four hands are up, they lower the car on the ground, and then mechanic with lollipop give the "all clear" signal to the driver. After that, driver inserts the first gear and off he go.

Teams noticed that pit stop time is to "people dependent" and that all this will add almost a second to the pit time. So, they tried to reduce this dependency and eliminate human reaction time from equation.

In modern days, as everything in Formula 1, everything is automated and with that, less human dependent. Today, as soon as wheel nut is tight, before the wheel gun is of the nut, mechanic on the gun press the button on the gun and in same time continues to remove the gun from the nut. When computer get this signal from all four guns, front and rear jacks are automatically released, without human input. In the same time, before car touch the ground, "traffic light" on the gantry over driver head turns green and driver can put the car in first gear before car actually touch the ground. When car touch the ground, front jack man pool the jack out of the way, first gear is already inserted and off he go. In this case only human reaction time dependency is that of driver and front jack-man.

|

|

NOGUN back is reversing button to fit on the back of the Paoli wheel gun, enabling the user to reverse the gun rotation quicker than the standard manufacturer's shuttle. The gun back is designed to enable quicker direction change by the user, or to automatic change direction in the event that it is placed on the ground during a pitstop – for example in a one-man-one-wheel scenario. The NUGUN Gun Back is currently available for the "Paoli" 2000 and 2000-S, 3000 and 4000 models, the most widely used wheel guns in top-level motorsport. NUGUN is a proven product, as used by teams in Formula One, IndyCar, GP2, World Series by Renault, A1GP, ALMS and Le Mans Series. |

NOGUN quickShift is an auto-reverse gun back to suit Paoli's high-performance wheel gun range. The quickShift features an operator-controlled auto-reverse shuttle. The shuttle direction is pre-set by the operator, from either the top or bottom of the gun back, which provides a safe, secure shuttle position. This gun back has proven to be an operator-friendly, reliable solution to enhance the consistency, security and overall speed of wheel gun direction-change during the pit stop This gun back has proven to be an operator-friendly, reliable solution to enhance the consistency, security and overall speed of wheel gun direction-change during the pit stop. |

Back to the top of the page