Tires

"The aim of a driver and his team in setting up the car is to ensure that the tires operate in the best possible conditions. Only in this way will a tire, which is one of the fundamental components of a Formula1 car, perform to the limit of its potential"

Ayrton Senna from his book " Principles of Race Driving"

"The FIA GT Championship was holding a street race around the capital (of Romania) with a grid of race-tuned versions of every kind of supercar from Aston to Lamborghini, Maserati, Ferrari, Corvette and, not least, my humble Ascari KZ1...

...

The opening lap on new tyres was critical. They were the most significant factor in how a car handled. The bottom gripped the road, the side supported the weight as the car cornered and roled. When you braked or accelerated, the tyre stretched lengthwise like a baloon. Accelerating warmed the rears, but pushing too hard too soon overheated them and cost grip when it mattered most. If you didn’t work the front tyres it created an imbalance; they had to be pliable and tacky enough to cope with the super late braking and corner entry speeds of qualifying. The trick was to work the sidewal and surface simultaneously. If you overcooked it when they were cold, the wheels locked up. That was bad news when you were stil moving at 80mph because it burnt a flat spot that could later blister or puncture.

It was a delicate process, not to be rushed..."

Ben Collins from his book "The Man in the White Suit: The Stig, Le Mans, the Fast Lane and Me"

Blister- When the rubber on a tire gets excessively hot thus melting small patches of the tire causing it to bubble. It also shows a breakdown of the compound causing the tire to become oily thus losing grip.

Camber - Camber is the number of degrees that the top of the tire is tipped inward (negative camber) or outward (positive camber). It affects handling.

Caster or Castor - It affects handling and refers to the number of degrees the top of the kingpin or spindle leans towards the rear of the car.

Compound - Refers to the different grades of tires. Different compounds have different rubber formulas. It can refer to the relative hardness of the tire.

Contact Patch - The area of the tires that makes contact with the racing surface. Air pressure, the load on the tire, caster and camber adjustments all factor into the size and performance of the contact patch.

Load - The tire load refers to the amount of weight placed on a tire. The heavier the load, the bigger the contact patch and the more grip the tire should have. This load shifts throughout a race lap. In every corner the load is shifted to the side, during acceleration it is shifted to the back, and under braking it is shifted to the front. Tires are constantly being loaded and unloaded.

Sidewall - The outside wall of a tire. Directly affects how the tires and chassis performs under load. Often referred to as sidewall flex.

Toe– Refers to the angle of the front tires when looking at them from the top. Toe In refers to the front tires pointing towards each other to a point at the front of the kart. Toe out refers to the back of the tires pointing towards each other to a point at the rear of the kart.

On road car and on high performance racing car, they look almost the same, round black rubber thing rolling on the road. But hire all similarities stop. In fact, everything is different, except color.

Despite some genuine technical similarity, race tires and road tires are distant cousins. An ordinary car tire is made with heavy steel-belted radial plies and designed for durability - typically a life of 25,000 kilometres or more.

A Formula One tire is designed to last for, at most, 200 kilometres and - like everything else on a the car - is constructed to be as light and strong as possible. Even so, F1 tires are far tougher than those on road cars, which may be able to last for 20,000 miles or more, but would not stand a chance against the rigours of F1 racing.

That means an underlying kevlar, nylon and polyester structure in a complicated weave pattern designed to withstand far larger forces than road car tires. F1 tires are enormously complex items, which have to withstand a variety of massive forces - F1 cars decelerate at forces of 6G and corner at up to 5G. That means anything up to a tonne of downforce, 3 tonne of lateral loadings and 4 tonne of longitudinal loadings. During the race tires don’t stay smooth, the edges get sharp with rubber flash from wear, and they flexes and deform significantly under load, the shape is no longer that perfect simetrical shape, so easy to model in a wind tunnel.

|

In this picture you can see loaded (warped) tire on the testbed. In F1 the tire shape can have a significant impact on the car’s aerodynamic performance. Knowledge of the profile and contact patch shape is therefore vital to ensure that the key air flow structures are in their correct places. In order to ensure good correlation in the development process the Computational Fluid Dynamics (CFD) virtual tire and the wind-tunnel model tires must be accurate representations of the full-scale tires, with the correct shape profile and contact patch throughout the entire operating envelope. |

In modern F1 there is a real premium on understanding this phenomenon and being able to work with the changing shape of the tire so that the car’s aerodynamics are the best they can be at all times. With this in mind accurate modeling of this complex transient system is fundamental to ultimate performance. Structural models of the tire can help to predict and provide tire shape under load, and these can then be fed into CFD directly. Tires and in particular tire shape is a key for a car’s aero performance. The tire sheds vortices and wakes, and interacts strongly with wings and underfloors and that's why tires and optimal aerodynamics are inextricably linked.

The Teams have a number of tools at their disposal to ensure good correlation and they use a mixture of virtual modelling, model scale testing, whole/part car multi-post rig testing and on-track testing to improve their understanding of the car’s and tires performance. The motorsports tire manufacturers will use, amongst other equipment, a tire test-rig. The most advanced system is currently the electric motor driven MTS Flat-Trac™ LTRe which is installed at SoVA Motion in the USA. This machine can simulate speeds of up to 200 mph (320kph) and simulate forces of up to 30,000N. The key to it then, is to learn from this and to match the tires’ full scale true loaded shapes to the virtual CFD tire and wind-tunnel tire shapes, otherwise a significant amount of CFD and wind-tunnel development runs will be wasted as they will not correlate to the real life conditions.

The way the cars work on their tires is a combination of car design and tire usage and how the two are affecting each other. The racing tire is constructed from very soft rubber compounds which offer the best possible grip against the texture of the racetrack, but wear very quickly in the process. The dry tires are typically designed to function at between 100 and 110 degrees Celsius. Small tweaks to the tire design can make huge differences to the way a car performs, and there are many different ways to approach the building of a tire that define how the tread interacts with the track surface and how the tire deforms under load.

Teams want to gather as much information about the tires they are using from which they can draw conclusions about tire performance and degradation. The two key areas which can be measured are tire temperatures and pressures.

In the past, temperatures could only be measured when a car was in the pit lane, using a pressure gauge and a thermal probe. Miniaturisation of infrared-sensing technology, however, has allowed temperature measuring equipment to be incorporated into a car’s sensor package, providing real-time information on tire condition.

There few key methods for measuring tire temperature – external infrared (IR) sensors mounted close to the tire and measuring devices incorporated into the wheel to measure carcass temperature. Initially, single-channel IR sensors were used to measure the external temperature of a tire, but they could only monitor a narrow strip of the surface, so an overall picture of tire temperature could not be gained. This disadvantage has now been overcome with the development of multi-channel IR sensors that can measure up to eight sections of tire surface, all packaged in a unit weighing about 15 g. Versions of these sensors have also been mounted within the wheel rim itself, with a wireless connection sending the signals to a receiver unit. A glance at the rear floor of many cars in the pit lane will reveal an array of miniature IR sensors pointing at the rear wheels.

As with temperatures, in the past tire pressures would have been checked in the pit lane, but pit lane pressure varied from on-track pressures as the tires cooled down coming into the pits. Monitoring pressure is of equaly important as temperature readings. Pressure is dynamic and increases as the gas in the tire heats up and expands, and it is vital to track the operating pressures to ensure it is optimal. Wireless tire-pressure monitoring systems are now the norm in Formula One, and consist of a sensor unit mounted on the tire valve stem and a receiver unit in the main control electronics system.

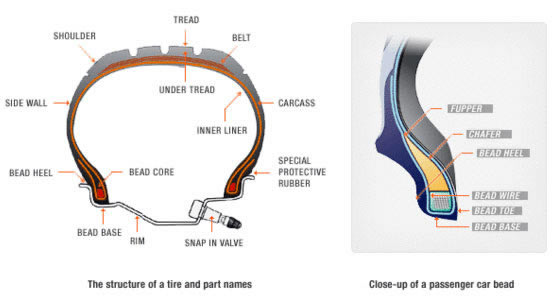

In simple terms, a tire is effectively made of rubber bonded to a 'carcass' - a hard material that creates the shape of the tire. That carcass can be made of a variety of materials, most commonly steel or some kind of composite.

The current F1 tires have a kevlar carcass. During season 2013 Pirelli tried steel construction, but after a series of failures, Pirelli has for several weeks wanted to return this back to kevlar as it used year before, but politics in what is a notoriously complex sport have prevented it from happening until later in the season, Hungarian GP.

They cost is about $1,600 a set (or $400 a tire). Team need 10 to 15 sets for weekend. The tyres cost each team in the region of two million euros a year. It is worth pointing out that a choice of tire manufacturer is not made by the teams or by the Commercial Rights Holder. According to Article 25.1 of the FIA Formula 1 Sporting Regulations, "a single tire manufacturer will be chosen by the FIA for subsequent seasons following an invitation for tenders to supply tires to all the cars entered in Championship Events for the duration of such subsequent seasons". Thus it is not correct to say that the choice of tire supplier is a commercial question as it is clearly written in the rules as being a regulatory decision. It is also clearly stated that there should be a tender for the next tire supply deal.

|

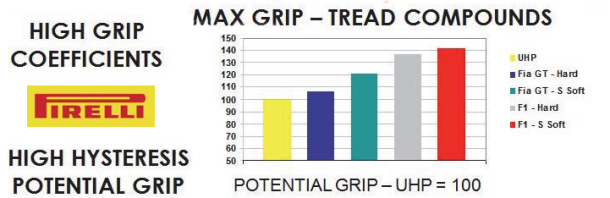

Comparing potential tyre grip for Ultra High Performance, FIA GT and F1 cars. (courtesy of Pirelli Motorsport Services Ltd., courtesy of Willem Toet, Head of Aerodynamics, Sauber F1 Team, Sauber Motorsport AG) |

The life of an F1 tire is dictated by either wear - literally it running out of rubber - or thermal degradation, where the conditions make it overheat to the point that grip reduces so much that the tire has to be changed. Usually, the timing of pit stops is dictated by one or the other.

The first classical law of friction states: “The size of the contact surface does not influence the friction”. Why, then, are tires for the Formula 1 racing cars so wide?

According to the “FIA Technical Commission”, the organization that decides on the technical rules for Formula 1, the front and rear tires should not be wider than stated in technical regulation.

The classical friction laws apply to materials that undergo mainly plastic deformation in the asperity summits. This in not the case for polymers (and elastomers). Polymers display a lower friction coefficient at higher nominal contact pressure (narrow tires - higher nominal contact pressure and vice versa). A high friction force can consequently only be achieved with a large surface area.

Other advantages of a wide surface are that the wear is distributed over a larger area, heat development per unit of surface is lower and the result is a larger heat-radiating surface.

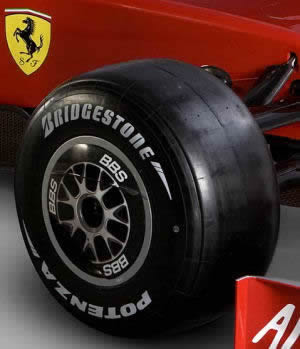

The development of the racing tire came of age with the appearance of 'slick' tires in the 1960s. Teams and tire makers realized that, by omitting a tread pattern on dry weather tires, the surface area of rubber in contact with the road could be maximised. Formula One cars ran with slicks until the 1998 rule changes came into effect, and new tire standards were introduced in an attempt to improve the spectacle of Formula One racing by reducing cornering speeds.

This led to the familiar sight of 'grooved' tires, the regulations specifying that all tires had to have four continuous longitudinal grooves at least 2.5 mm deep and spaced 50mm apart. These changes created several new challenges for the tire manufacturers - most notably ensuring the grooves' integrity, which in turn limited the softness of rubber compounds that could be used.

A tires shape is not a simple cylinder, the tire in fact has a complex shape, as the tire deforms in both side and front elevation as it contacts the track. This shape changes with steering and speed/downforce. Mapping this complex dynamic shape is important as it will feed back to correlate to the shape seen on the rubber wind tunnels tires provided by supplier and also modeled in CFD. The shape changes are subtle, but equally very different from tire to tire the flow off the front wing and around the rear end will be heavily influenced.

2009 season brings a much-welcomed return to slick tires, following the FIA's decision to limit aerodynamics rather than rubber as a way of keeping cornering speeds under control.

The 'softness' or 'hardness' of rubber compounds is varied for each race according to the known characteristics of the track. Two different compounds are available to each team at every Grand Prix weekend, and every driver must make use of both specifications during the race. The actual softness of the tire rubber is varied by changes in the proportions of ingredients added to the rubber, of which the three main ones are carbon, sulphur and oil. Generally speaking, the more oil in a tyre, the softer it will be.

|

|---|

Bridgeston Potenza Formula 1 tires, left slick, for dry track, middle Intermediate, for partially wet conditions, and right full wet tires for rain conditions |

Intermediate and wet-weather tires have full tread patterns, necessary to expel standing water when racing in the wet. One of the worst possible situations for a race driver remains 'aquaplaning' - the condition when a film of water builds up between the tire and the road, meaning that the car is effectively floating. This leads to vastly reduced levels of grip. The tread patterns of modern racing tires are mathematically designed to scrub the maximum amount of water possible from the track surface to ensure the best possible contact between the rubber and the track.

The intermediate tires are generally used in partially wet conditions, where the driving surface is neither completely dry nor absolutely drenched. They provide moderate assistance in both conditions and are hence favoured when half the circuit is experiencing rain and the other half remains dry.

Heavy grooved, full rain tires will come into play in case of rains. When the treads in the tires, come in contact with the track, they expand a little, due to the downforce and the weight and absorb enough quantity of water to bring the tire back in contact with the track. When the water soaked area of the tire lifts off the track, it contracts again and releases the water. Thus tires play an important safety role by keeping the car from sliding off uncontrollably.

Formula One tires are normally filled with a special, nitrogen-rich air mixture, designed to minimise variations in tire pressure with temperature. The mixture also retains the pressure longer than normal air would.

It is supplier who decide dimension inside Technical rules prescribed limits. Unlike the fuel, the tires bear only a superficial resemblance to a normal road tire. Whereas a road car tire has a useful life of up to 80,000 km, an Formula One tire is built to last a bit more then one half of race distance (a little over 200 km).

This is the result of a drive to maximize the road-holding ability (grip), leading to the use of very soft compounds (to ensure that the tire surface conforms to the road surface as closely as possible.

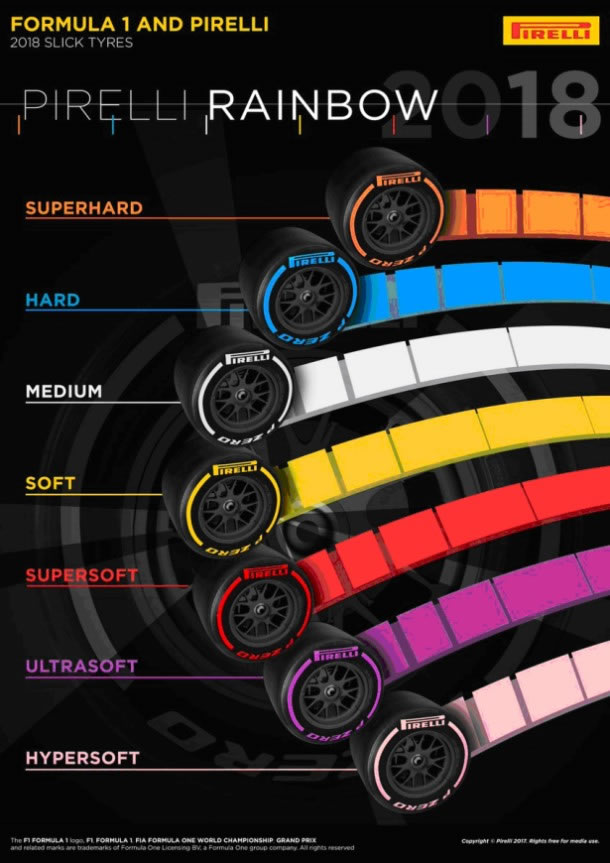

Since the start of the 2007 season Bridgestone was the exclusive tire supplier and have introduced five compounds of tire, two of which will be made available at each race. The harder tire is more durable but gives fewer grips, and the softer tire gives more grip but is less durable. As the names suggest, the tires are graded in terms of durability, with the 'super-soft' the least durable and the 'hard' the most.

At each race, the company supplies two tipes of tire, both of which must be used by each driver at some point in the race. The two types are called 'prime' and 'option', but each can be any one of the four different tires - 'super-soft', 'soft', 'medium' and 'hard'."Prime" tire is harder of two, and "Option" is softer. Street circuits, such as Monaco and Singapore, tend to require softer tires. Fast circuits, such as Spa, Silverstone and Suzuka, harder ones.

Both compounds supplied by maker have to be used by teams during one race and the softer tire of two, until 2009, has a painted green stripe on the inner and outer sidewalls of the tire. This was introduced after the first race of the season when confusion occurred because a small dot was put instead of the white stripe.

Each team must use each specification during the race, unless wet or intermediate tires are used during the race, in which case this rule no longer applies.

From 2010, only tire change was allowed during pitstop. Refueling was banned, and drivers have to start with all fuel needed for race. This will put additional load to tires because until 2010, car was loaded with 50 to 60 kilograms of fuel, and now this load is about 150 to 170 kilograms at the beginning of the race.

And there is another thing to consider. With refueling, pitstop duration was about 6 to 9 seconds, and a plenty room for good strategy and overtaking trough pits. Without refueling pitstop duration is around 3 to 4 second and strategy should be impeccable. Often this short time can't be used for any meaningful strategy.

But anyway, during pitstop in one typical Formula 1 race there were places to be won and lost to other drivers by mistiming the stop, so how did the teams decide?

The teams have a more sophisticated timing system than the one available to the public and media. It divides the lap into ten sectors, rather than the basic three available for rest of us and this gives them a much faster evaluation of the way the tires are behaving. Rather than wait 20 plus seconds to find out whether they are going off, they can tell every (more or less) 8 seconds how the performance is going.

Engineers and computers study the trends and make the strategy calls based on what they see.

This works in two ways; it tells them the precise moment when their tire compound are losing performance, and by reading the sectors of cars already on different compound, they can see what performance gain rivals are experiencing.

After one driver has pitted and his lap times went from 1m 19.7s (old tires) to 1m 17.6s (new tires - different compound). Rival engineers could see immediately the speed advantage he was getting from his new tires and decide to do and when to do their pitstop.

| 2010 - Out | 2011 - In |

|---|---|

Following Bridgestone’s decision to withdraw at the end of 2010 after 13 years in Formula One, Pirelli take over as the sport’s sole tire supplier. The Italian company, last part of F1 in 1991, will provide all teams with rubber for the next three years.

Tire allocation has been reduced for 2011, with 11 rather than 14 sets of dry-weather tires available to each driver per race weekend. Drivers will receive three sets (two prime, one option) to use in P1 and P2 and must return one set after each session. A further eight sets will then be at their disposal for the rest of the weekend, although one set of each specification must be handed back before qualifying.

If a driver fails to use both specifications of dry-weather tires during a (dry) race, they will be excluded from the results. If a (dry) race is suspended and can’t be restarted, and a driver has failed to use both specifications, 30 seconds will be added to the driver’s race time.

Official F1 tire supplier Bridgestone have in middle of February 2009, settled on how to differentiate its compounds of dry-weather slick tires. This system of color-coding has continued with new supplyer, Pirelli.

Pirelli's motorsport director Paul Hembery think that these will enable both live and television audiences to tell at a glance who is on what compounds, which will be vital knowledge as tires are set to form a key part of race strategy 2011.

But the key change from 2015 is that the teams will be given a greater amount of choice over which tire compounds they can use over a race weekend in the hope of mixing up race strategies, spice up the racing and improving the show. For the first time, Pirelli will make three, rather than two, dry-weather compounds available at each event, with the teams free to choose 10 of the 13 sets at each driver’s disposal. The result is a system whereby drivers have a degree of choice over which compound they have available during a race weekend. That in of itself should open up plenty of strategy options, not least because the teams now have the option not just of running different rubber to their rivals, but also different compounds amongst their own drivers. Unlike in previous seasons when Pirelli nominated two of their four slick tire compounds for each event, Pirelli will nominate three of the five for a race weekend. Here’s how it will work:

- One set after the first 40 minutes of FP1

But there’s a catch too. Because of the logistics problems in providing a wider variety of tires and then shipping them around the world, the teams have to submit their choices for each round no less than eight weeks before the start of each European round and 14 weeks before the start of races on other continents. That meant that selections for the first two rounds of the season had to be made before the turn of the year, long before any 2016 car had turned a wheel in anger. So, the teams, with little knowledge of how the 2016-spec tires will behave, will have had to gamble on which compounds to select. After extensive aero rules changes for 2017, biggest overhaul of the aerodynamic regulations in almost 20 years. The 2017 rules will see a reversal of key changes introduced during the past two decades. The narrow-track format introduced in 1998 will be banished and two-metre wide cars, last seen in 1997, will return. And it isn't just just the chassis which is getting wider – so are the tires. The main source for slashing lap times will come from the wider Pirelli rubber, so width of the tires changed up from 245mm to 305mm and 325mm to 405mm, at the front and rear respectively. Striking change. The increased contact patch will drastically improve mechanical grip, improving low speed performance and allowing the driver to attack high speed corners with even more confidence.

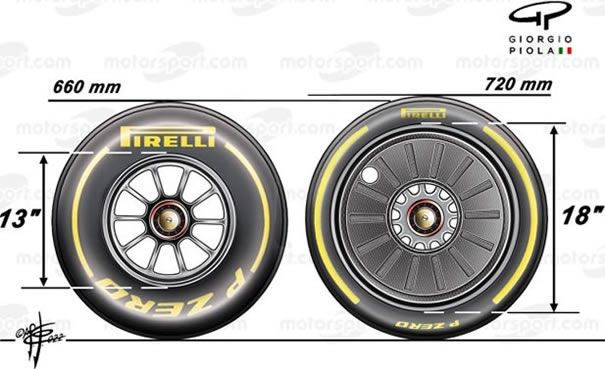

For decades, F1 cars have run on 13-inch wheels, wrapped in tires with high-profile sidewalls. But as part of 2022's radical technical shakeup, the sport is now joining much of the rest of the racing world as it adopts 18-inch wheels and new, low-profile racing rubber. The super-hard and hyper-soft compounds will be added at either end of the 2017 range of tires, with two new colours added to Pirelli's sidewall branding across the range. The super-hard will be orange, the hard 'ice blue', the medium white, the soft yellow, the super-soft red, the ultra-soft purple and the hyper-soft pink.

Pirelli takes 1,500 tires to every GP and they have to cut and destroy any unused tires at the end of each weekend because they have to glue the tires to the rims. All Pireli tires are recycled after use. During 2012 season Pielli provided teams with 31.800 racing tires. In that number proportion of used tires was: 6% supersofts, 25% softs, 21% medium, 17% hard, 18% intermediate, 11% wet and 2% developement tires.

On the beginning of 2013, Red Bull Racing broke the previous pit-stop record held by McLaren. This happened during Malaysia GP. In fact, having reviewed the data, they beat the previous record on five separate occasions during the race. McLaren changed Jenson Button's four wheels in 2.31s at the German Grand Prix 2012, but the Milton Keynes squad bettered that mark by quite some distance. These times are all taken from the car data which each team uses to record the stationary times. TV do their own rough calculations, though for real precision the common practice in the pitlane is to use the car's own datalog. Red Bull stationary pit stop times in Malaysia: It's basically a blink-and-you'll-miss-it change of the tires. |

2019: what are the 2019 Formula 1 tires?

Purple, pink, ice blue and orange tires? They're not going to be around any longer with Pirelli going back to basics.

White – Hard Tire

Yellow – Medium Tire

Red – Soft Tire

That will be the colours used on any track. Along with an intermediate and extreme wet tire which will be used as when they're needed and for fans of the sport, that's more or less what you need to know about the tires. For normal fan, but not for us.

Colour-wise, things are simple, however despite Pirelli bringing the three-colour-tires to every event, the compounds for the tires will be slightly different depending on the circuit and race track.

There's five different compounds ranging from C1 to C5 – C1 is the hardest and C5 is the softest.

The first four races of the season, the tires have already been announced by Pirelli.

In Australia for example, the three colours will be available. The white (hard tire) will use compound C2 which means it's pretty durable and long-lasting. The Yellow (medium tire) will be C3 and the Red (soft tire) will be on the C4 compound.

In Bahrain, it's a different story – the compounds used for that race track are C1 (White - hard tire), C2 (Yellow - medium tire) and C3 (Red - soft tire).

As it was last season, the teams are all required to select sets (from 13 dry tyres from the three compounds on offer) no less than eight weeks before the start of each event which is held in Europe and 14 weeks before the start of each event held outside of Europe.

Also in 2019. tires are moving to a thinner tire tread and this is all to help combat blistering problems which was seen throughout the last couple of seasons.

To know more see the articles:

Formula 1 Tire Suppliers - History

Tire Compouns

Tire Warmers

Using Tires

What is the most important part of a racing car?

Explanation of tire simbols find on "normal" tires

TIRE SIZE

1-Tire width (mm or inch)

2-Aspect ratio in %

3-Radial construction

4-Rim diameter

5-Load index

6-Speed symbol

7-Tire outer diameter (inch)

8-Ply rating

Beginning in 1991, the speed symbol denoting a fixed maximum speed capability of new tires must be shown only in the speed rating portion of the tire's service description, such as 225/50R16 89S. The most common tire speed rating symbols, maximum speeds and typical applications are shown below:

L |

75 mph |

120 km/h |

Off-Road & Light Truck Tires |

M |

81 mph |

130 km/h |

|

N |

87 mph |

140km/h |

Temporary Spare Tires |

P |

93 mph |

150 km/h |

|

Q |

99 mph |

160 km/h |

Studless & Studdable Winter Tires |

R |

106 mph |

170 km/h |

H.D. Light Truck Tires |

S |

112 mph |

180 km/h |

Family Sedans & Vans |

T |

118 mph |

190 km/h |

Family Sedans & Vans |

U |

124 mph |

200 km/h |

|

H |

130 mph |

210 km/h |

Sport Sedans & Coupes |

V |

149 mph |

240 km/h |

Sport Sedans, Coupes & Sports Cars |

Z |

149 mph + |

240 km/h + |

Sport Cars |

W |

168 mph |

270 km/h |

Exotic Sports Cars |

Y |

186 mph |

300 km/h |

Exotic Sports Cars |

While a Z-speed rating still often appears in the tire size designation of these tires, such as 225/50ZR16 91W, the Z in the size signifies a maximum speed capability in excess of 149 mph, 240 km/h; the W in the service description indicates the tire's 168 mph, 270 km/h maximum speed.

Most recently, when the Y-speed rating indicated in a service description is enclosed in parentheses, such as 285/35ZR19 (99Y), the top speed of the tire has been tested in excess of 186 mph, 300 km/h indicated by the service description as shown below:

285/35ZR19 99Y |

186 mph, 300 km/h |

285/35ZR19 (99Y) |

in excess of 186 mph, 300 km/h |

End of 2014 bring new Ferrari FXX-K supercar with 1050 bhp. Together with all wonderful stuff, Pirelli bring special tires for this car. You will not find it on the shelves of your local tire shop for some time, but technology is mooving forvard. Pirelli slick tires ensure the FXX-K stays keyed into the track surface, and they come complete with sensors that monitor longitudinal, lateral and radial acceleration, as well as temperature and pressure, and relay everything the engineers need to know about what’s happening at the tire-road contact patch. This ensures an accurate analysis of the interaction between the tire and track surface, providing even more vital data to enable the traction control system to guarantee maximum performance. The electronic differential, traction control and Ferrari's genius Racing SSC (Side Slip Angle Control) system are all specifically programmed to suit the car’s more aggressive set up and work with info recieved from the tires.

Back to the top of the page