ECU - Electronic Control Unit

MES - McLaren Electronic Systems

Fast Facts

Sensors on a Formula One race car: 150 - 300

Data generation rate while racing: 100 kilobytes to 0.5 megabytes per second

Data generated during 1 Grand Prix race per car: 1 to 2 gigabytes

Data generated during 1 Grand Prix weekend: 100 gigabytes, that's equivalent of 250 DVD-s

ECU data collected per car per year (including practice laps and equipment testing): 2 to 3 terabytes, that's equivalent of nearly 5000 DVD-s

Application Platform Capabilities: Development, Data Management

Twenty-five or so years ago, Alain Prost won his fourth world championship – and promptly retired. The car in which he achieved this final success, and which took Damon Hill to his first  Grand Prix victories in the same year, was the technologically remarkable Williams-Renault FW15C. This was the ultimate electronic aids car before most of the technology was banned for 1994 and beyond. It featured active ride, traction control, ABS braking, a set-up that could be adjusted between corners and the ability – at the switch of a cockpit button would lower the rear of the car and stall the diffuser, which reduced the drag of the car considerably. This was incorporated via the software to give the engine an extra 300rpm when used. It was effectively a 'push-to-pass' button. There was also electrically-powered braking assistance – also to help the drivers exploit the increased braking potential arising from the downforce increase. The driver could choose to use the paddles behind the steering to change gear semi-automatically, or to leave it in auto mode when it would change up and down automatically at the appropriate time. As soon as the driver touched the paddles, it would revert to manual mode. Driver could also choose the car's angle of attack by adjusting the front ride height via a knob. The ideal rake angle will vary according to the speed of the corner. This feature was automated, so the car would continually be changing its own set-up. In terms of the electronic 'goodies', the FW15C can be considered the most advanced F1 car of all time, even though knowledge has advanced enormously since 1993.

Grand Prix victories in the same year, was the technologically remarkable Williams-Renault FW15C. This was the ultimate electronic aids car before most of the technology was banned for 1994 and beyond. It featured active ride, traction control, ABS braking, a set-up that could be adjusted between corners and the ability – at the switch of a cockpit button would lower the rear of the car and stall the diffuser, which reduced the drag of the car considerably. This was incorporated via the software to give the engine an extra 300rpm when used. It was effectively a 'push-to-pass' button. There was also electrically-powered braking assistance – also to help the drivers exploit the increased braking potential arising from the downforce increase. The driver could choose to use the paddles behind the steering to change gear semi-automatically, or to leave it in auto mode when it would change up and down automatically at the appropriate time. As soon as the driver touched the paddles, it would revert to manual mode. Driver could also choose the car's angle of attack by adjusting the front ride height via a knob. The ideal rake angle will vary according to the speed of the corner. This feature was automated, so the car would continually be changing its own set-up. In terms of the electronic 'goodies', the FW15C can be considered the most advanced F1 car of all time, even though knowledge has advanced enormously since 1993.

The FW15C was an evolution of the FW14B that had taken Nigel Mansell to the 1992 world championship. The 14B had been an active ride adaptation of an existing car, but the 15 was designed at the outset around the new technology, under the technical directorship of Patrick Head and Adrian Newey. Paddy Lowe was the systems engineer who wrote and developed most of the software necessary to make the active ride system work.

For '94, the governing body banned active ride and most of the associated 'automatic' electronic technology – and a new, different era of F1 began. Some would say "GOOD OLD TIME".

Formula One racing represents the highest class of auto racing, and is constantly pushing the leading edge of technology. Computers have long been used in designing and optimizing the complex settings for race cars, and for collecting onboard data that is transmitted back to support teams on the pit wall. A key component is the ECU, which gathers data from sensors on the car and wirelessly transmits data to race team support crews.

As part of its ongoing efforts to control costs, provide a level playing field for racing teams, and sustain safety, the FIA in the spring of 2006 invited manufacturers of automotive electronics to propose a standardized ECU for inclusion in all Formula One cars for the 2008, 2009, and 2010 championships. The FIA chose the ECU solution developed by McLaren Electronics Systems and Microsoft and its semi conductor supplier Freescale, and awarded the joint-effort the contract to supply the solution to all competing Formula One teams.

McLaren Electronic Systems, an independent company of the McLaren Group of companies, which includes the famed McLaren Racing organization, is a supplier of advanced motorsport control and development support systems including the engine control unit (ECU) that manages the complex engine, transmission, steering, suspension and other key elements of Formula One race cars. ECU-s are based around Freescale’s 32 bit MCU, which is built on four, 200 megahertz Power Architecture cores. Official name of the unit is TAG-310B ECU.

The solution comprises the power train control, data logging and telemetry control components on the car and also a central data server in the garage which receives data from the car, logs it for near instant analysis and redistributes it to client tools of the racing team's choice. (NB McLaren can also provide the client tool capable of both receiving real time and interrogating historical data). The in-garage components (data server and client tool) are known as ATLAS (Advanced Telemetry Linked Analysis System).

|

|

Formula 1 ECU, MES McLaren Electronic Systems, TAG310B |

Formula 1 ECU, MES McLaren Electronic Systems, TAG320 |

Having run the McLaren Electronics Systems TAG-310B ECU since 2006, teams will have an option to run an upgraded ECU in 2013. The new model, TAG-320, is the same physical size, but has far greater performance and more interfaces. Although useful, for 2013 this has no real impact on the teams, as the ECU is aimed at supporting the complex power units to be introduced in 2014. During 2013 presentation of the new F138 car, only (in my knowledge) Ferrari have chosen to introduce - ahead of schedule - the new TAG-310B ECU control unit that will be used in 2014. This has involved a lot of work to integrate and control all its features in terms of both software and hardware, but give a some advantage to the team to prepare for 2014.

The triangular box is often sited inside the cockpit in the below the driver’s legs, while some teams mount it in the sidepod. Being air-cooled, the sidepod location is convenient for cooling and wiring, but being a rather large and moderately heavy device, sidepod mounting requires aerodynamic and centre of gravity compromises.

The ECU monitors all aspects of the power train and gathers data from 150 to 300 sensors located on each car. Generating between 100 kilobytes and 0.5 megabyte of data per second, one car's ECU will potentially gather more than 1 gigabyte of information from the sensors during a grand prix race, with all of it continuously broadcast in real time back to systems located in the track-side garage of each Formula One car. Here the ATLAS data server must log the data without loss and provide the means for Engineers to almost instantly retrieve and analyze the data. In addition, where not all the data could be transmitted for example due to restricted bandwidth, on returning to the garage the missing data is taken directly from the car and the gaps automatically filled in by the server.

McLaren Electronics and Microsoft have worked together closely, developing Formula One technologies. The ECU data, collected during practice laps and racing, as well as from testing equipment in the garage and from factory simulators, has proven so valuable that McLaren Electronics wanted to provide a storage solution that made it easier and faster to retrieve telemetry data stored in specially developed, highly efficient files. In addition the company wanted to make this data available through other tools such as Excel with a standard Open Database Connectivity (ODBC) or Object Linking and Embedding Database (OLEDB) data access capability, without the need to understand the file formats being used.

McLaren Electronic Systems saw immediate value in the Microsoft Application Platform and, in particular, the FILESTREAM feature of Microsoft SQL Server® 2008 database software. New for SQL Server 2008, FILESTREAM integrates the SQL Server Database Engine with the NT File System (NTFS) by storing binary data as files on the file system while letting the data remain an integral part of the database and maintaining transactional integrity. Transact-SQL statements are used to insert, update, query, and back up the FILESTREAM data within the database. In the meantime the existing client tool can use Win32 file system interfaces for streaming access to the data as if reading and writing to a file.

The essence of the problem they faced was how to deal effectively with a high volume of time series data," says Paul Spence, Product Director with McLaren Electronic Systems. "Prior to SQL Server 2008, this was not something that we felt any database could really handle properly."

Working with Microsoft and Conchango, a Microsoft Gold Certified Partner specializing in enterprise data integration, McLaren Electronics executed a proof of concept (PoC) project to test the efficiency of FILESTREAM. The PoC was a success and McLaren Electronics and Conchango are now fully developing the solution using SQL Server 2008 and its FILESTREAM feature at its core.

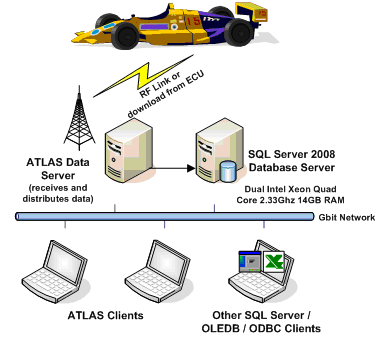

Basic architecture of the McLaren Electronics solution

created and deployed using the Microsoft Application Platform

Architecture

The McLaren Electronics solution has a multi-tier architecture that includes:

- ECU. The McLaren Electronics ECU is the onboard hardware device with embedded code that gathers data from the Formula One car's engine, transmission, suspension system, frame components and other key elements, encrypts the data; and transmits it to the trackside support team. McLaren Electronics ECU consist of few separated parts or elements (links to official McLaren Electronic Systems Limited site):

- TAG-310B SECU is the main processing unit for powertrain control of a racing car. This is older version in use since the start of the 2005 till 2013 by all F1 cars.

- TAG-320 SECU is the main processing unit for powertrain control of a racing car. This version is in use after 2013.

- LIU-4 interface unit provides signal conditioning for four five-wire LVDT (Linear Variable Displacement Transducer) positioning sensors, which are used for measuring the damper and thus suspension travel. Outputs from sensors are directed trough interface unit uo ECU through a CAN interface.

- PB2006 ignition/injection power unit provides regulated power supplies for engine and other electrical systems around the car as well as providing the high power ignition and injection drive stages for eight cylinders. The power box also regulates the power supply from the alternator and passes it to the car’s battery. At some1.5 kg in weight and more than 25 cm long, the Power box is a large item to package, but requires only air cooling.

- LRX-310B microwave receiver module with integral antenna can provide lap timing when used with compatible ECU and track-side transmitter.

- HIU-3 (hub interface units) are used at each corner of the car to interface to TPMS (Tire Pressure Management System) sensors located at the wheels either attached directly to the wheel or as part of the valve, and they send tire pressure data wirelessly to an aerial mounted centrally on the car, which in turns sends the signals back to the ECU via two-wire CAN network. In this way is vastly reduced the number of wires through the wishbones.

- EDR-400 is a compact, self-contained high speed data logger developed specially for on-board racing applications. The unit provides 42 direct inputs, and additional inputs via CAN-linked sensor interface units. The unit comes with 1Gbytes integrated logging memory, GPS and integrated 115.2kbps telemetry option. This unit is troublesome to fitt because of its 0.6 kg weight, and its 12 x 15 cm size, means it is hard to find space in the sidepods.

- CBM-470B telemetry unit is for motorsport and automotive applications designed to support wireless data transfer and provide local data logging. The unit is based around an Intel Atom processor core running a highly optimised Linux based RTOS. - ATLAS Server. ECU data from the car is sent to the ATLAS server solution developed by McLaren Electronics, initially using the Visual Studio® 2005 development system, and now Visual Studio 2008. The ATLAS Server unpacks the telemetry data from the ECU and multicasts it to ATLAS client software being used by support crews.

- ATLAS Remote Data Server (RDS) enables live telemetry to be viewed simultaneously in different parts of the world. Several Remote Data Servers can be daisy chained together so that live telemetry data can be analysed at the track, factory and at the engine supplier

Often the available internet bandwidth available from a racetrack is limited, so it is not possible to get all the data back to the factory as quickly as might be desired. The RDS ensures that most recent data arrives first and then older data is backfilled when there is available bandwidth - ATLAS Client. The ATLAS Client software runs on support team computers, usually laptops in the garage. The ATLAS Client provides near real-time display of data and corresponding graphics that help support teams to monitor the health of the racing car across a spectrum of parameters. The ATLAS client, developed by McLaren Electronics, runs on the Microsoft Windows XP or Windows Vista operating system. Microsoft Office Excel 2007 spreadsheet software is used for additional data analysis and visualization. On large racing teams there can be more than 30 support team members studying ECU data on their laptops during a race, with one set of engineers and technicians studying transmission feeds, while others analyze telemetry data from the engine, suspension, and other systems.

- ATLAS Database. The Atlas Database offers McLaren Electronics a relational database for ECU data to provide an easily searchable central repository. Hosting ECU data on Microsoft SQL Server 2008 running on the Windows Server® 2008 Enterprise operating system, using the FILESTREAM feature for faster access, will provide seamless access to historic ECU data - - whether from previous races, test lab simulations, or just the last lap run. Conchango is working with McLaren Electronics and Microsoft to create the database solution. The database schema includes all of the metadata about the race, test, or other ECU-generating event. The schema also includes a specific session data table with the file stream BLOB column for each ECU-generating event. The solution also uses the common language runtime (CLR) hosted within SQL Server. When an ECU data set is requested, a CLR function expands the binary data as a parameter result set so that it can then be consumed by reporting and visualization tools such Office Excel 2007 and SQL Server 2008 Reporting Services.

- The car must also be equipped with an FIA Accident Data Recorder (ADR), which stores data from all the car’s key sensors and two FIA-specific accelerometers. These allow the FIA to use the SDR as an aircraft-style black box recorder to gather data on accidents. Should the car be in a major crash, the SDR will trigger an medical warning LED light on the cockpit top to warn marshals of the severity of the accident, to allow them to take appropriate care with the driver.

Fast and Seamless Data Access using FILESTREAM

One of the factors behind the need for speed in accessing data is that race teams collect so much information. "A racing team might collect 2 or 3 terabytes of data per year, and need the ability to access 4 or 5 years worth of data," says Spence. "So the volumes are large. SQL Server 2008 enables us to use the FILESTREAM mechanism to point to a BLOB and stream it, providing much faster access than we would get through a typical table query."

The unpredictability of racing is another major force behind the need for immediate access to large volumes of ECU data.

"The reasons teams gather so much information is that you're never absolutely certain as to what you will need to look at during a race or during a test," says van Manen. "What you do know is that any decision making, especially during a race, will have to be made nearly immediately. A team has a massive amount of data to guide their decisions, but they need the ability to access that data swiftly and precisely. If they need to compare data points with earlier runs, all of the earlier examples need to be immediately accessible for comparison. With Formula One, you are operating within a very impatient world."

Spence agrees about the demands of working within an impatient world: "The most important thing to the team is the speed of access. "We all know how frustrating it is if you load something on a computer and you have to wait for a minute. When you're in the racing environment the pressure is intense. You need a robust, high-performance system when you've got someone shouting at you, 'We need to know what to do before the car goes!' The proof of concept demonstrated that SQL Server 2008 and FILESTREAM clearly outperformed our file system, while greatly improving data integrity."

The combination of performance, data integrity, and robustness has made McLaren Electronics eager to offer its database solution to all Formula One teams.

"To support the racing teams we need three things from a database: performance, integrity, and robustness," says van Manen. "If you can find all three, you've got a winner. SQL Server 2008 wins on all three points."

The essence of the problem we faced was how to deal effectively with a high volume of time series data. Prior to SQL Server 2008, this was not something that we felt any database could really handle properly."

The ECU generates data on 500 to 1,000 parameters that are of continuous interest to the pit-side crews, and there's another 10,000 data points that are examined less frequently to guide diagnostics. … Moving all of this to SQL Server 2008 greatly simplifies data management."

With the advent of the SECU (Single specification ECU provided by McLaren Electronics) nothing can be controlled from the pitwall.

The SECU will monitor around 120 functions, these range from engine and geabrox parameters, to temperature sensors, Driver heart beat, brake wear and even pressure sensors for the aerodynamics. Here is the list of dedicated sensor inputs to ECU TAG-310B:

This is the defintive list...

Engine air valve pressure 1

Engine air valve pressure 2

Engine air valve tank pressure

Airbox air pressure

Ambient air temperature

Cam sensor

Crank sensor 1

Crank sensor 2

Injector supply voltage

UEGO Sensor left bank

UEGO Sensor right bank

Gearbox shift drum position 1

Gearbox shift drum position 2

Gearbox input shaft speed

Clutch position 1

Clutch position 2

Clutch actuator hydraulic pressure

Lateral Acceleration

Longitudinal Acceleration

Differential actuator hydraulic pressure

Engine throttle position 1

Engine throttle position 2

Hand controller demand

Throttle Pedal Input 1

Throttle Pedal Input 2

Front Brake pressure

Rear Brake pressure

Hand controller enable

Hydraulic System pressure

Lap Trigger

Garage Mode Select

Engine kill ignition switch

Front Left Wheel speed

Front Right Wheel speed

Rear Left Wheel speed

Rear Right Wheel speed

Gearbox oil pressure

Engine oil pressure

Engine crankcase pressure

Engine coolant pressure

Fuel Pressure

Fuel Collector Pressure

Fuel Collector Level

Gearbox oil temperature

Engine oil temperature

Engine coolant temperature

Fuel Temperature

Exhaust Temperature Left

Exhaust Temperature Right

Spare Analogue Input 1

Spare Analogue Input 2

Spare Analogue Input 3

Spare Analogue Input 4

Spare Analogue Input 5

Spare Analogue Input 6

Spare Switch Input 1

Spare Switch Input 2

Spare Switch Input 3

Spare Speed Input 1

Spare Speed Input 2

Spare Speed Input 3

Spare LVDT 1

List of McLaren Electronic Systems Limited products in use in Formula 1 car can be seen on official page. Folow this links:

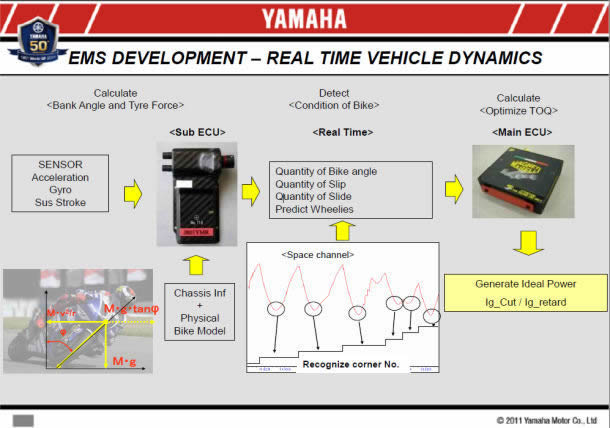

Example of structure of MotoGP ECU, in this case Yamaha YZR M1 2010

We can se that degree of sophistication in this elite motosport class is same as in Formula 1.

Back to the top of the page