Clutch Upgrade For Road Car

This article is all about finding the optimal clutch plate, pressure plate and flywheel combination which will suits your road going cars, and some drag race street going cars.

I will explain few considerations and try to give you some options to make you easier to find proper setup for you. Your choice depend how you use your car and your priorities. Comfortable driving..., harsh driving..., sporty driving..., drag racing...!

And on the end, my recommendation.

First of all, read my article about Clutch here to know in more details how clutch work.

The clutch is one of the most frequently replaced components on a high-performance car (with brake pads and tires, that is). So it helps if you can understand the basic concepts yourself without relying on other people's advice. Read this and you'll be able to talk about clutch configurations, their applications and how you might possibly be able to improve your own car's wavering clutch!

The clutch disc is probably the most frequently abused bit of hardware on a high-performance car. It's the poor little thing that gets squeezed in between the engine's flywheel and the pressure plate (clutch cover). In this position, it can often be subjected to massive loads as well as intense heat. Sometimes on even just a slightly modified car, the clutch can prove to be the weak link of your car.

Here are the possible solutions to the problem, and the low-down on current clutch technology:

Considerations

To find an effective solution to a clutch problem, you firstly need to consider the application of the replacement clutch package. Factors that need to be considered are available tire traction, gearing, driving style, engine torque at certain rpm, and the amount of load frequently placed on the engine. That's sort of a fancy way of saying how hard the car gets driven! All of these contributing values will have a bearing on what is the right combination for you. But it is important not to just focus only on the clutch plate, as the flywheel and pressure plate also play a major role. It's a good overall package that we're looking for.

Types of Clutch Plates

Clutches come in a variety of sizes - the limiting factor in their diameter is the space available within the bellhousing. As a guide, most Japanese cars (even the high-performance ones) come with an 20 to 22 centimeter clutch, while a Commodore V8 comes with a larger plate diameter of around 25 to 28 centimeter.

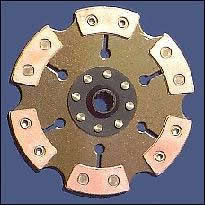

Paddle/Puck/Button Clutches

These clutches are sometimes quite unusually shaped and have relatively small areas of friction lining on each paddle. This serves to reducing the overall contact area acting upon the flywheel when compared to a full-face clutch. With no other accompanying changes, fitting one of these will give a higher maximum clamping pressure (pressure = force / area) and will therefore deliver more resistance to slip. There are, however, some problems with simply installing a paddle clutch with no other changes. Because the total contact area of the clutch is reduced, the rate of lining wear is increased, clutch engagement is more sudden and shudder can also be encountered on take-off.

Full-Face

There are full-face clutches in the form of full circle clutch plates, which are fitted with full circle area of friction material. These come with a varying amount of lining area (narrow or wide). The appropriate pressure plate rating and engagement smoothness depends on the area and fabrication material of the lining. The clutch plate itself is often more substantial in construction when compared to the more sculpted paddle types. The trade-off being increased mass.

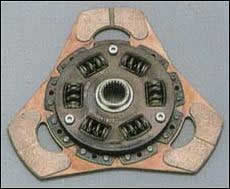

Hybrid

There are combination full-face/paddle clutches now appearing in the form of full (or near full) circle clutch plates, which are fitted with small areas of friction material. These come with a varying amount of lining area and are a great compromise for someone after some of the advantages of both full-face and paddle clutches. The appropriate pressure plate rating and engagement smoothness depends on the area of the lining material of the individual clutch plate. The clutch plate itself is often more substantial in construction when compared to the more sculpted paddle types - the trade-off being increased mass.

Multi-Plate

Multi-Plate clutches are becoming increasingly popular in the aftermarket, especially amongst high-performance Japanese vehicles. But theoretically, they should only be used where there isn't enough room for a larger diameter clutch. In the case of a multi-plate design, the total friction area is greatly increased, as there are multiple clutch plates. The advantages include an ability to get away with low rated pressure plate, which gives lighter pedal weight. The trade-offs are the possibility of shudder and noise during operation and increased mass. Only the more expensive high-performance factory vehicles, such as the twin-turbo V8 Lotus Esprit, run a twin-plate clutch as standard.

Clutch Centres and Cushioning

Most factory cars come fitted with a sprung centre to aid engagement smoothness. These units have a series of small springs located radially around the hub that allow the clutch assembly to rotate slightly upon engagement to the flywheel. This helps to smooth out any torsional fluctuations and vibration that would otherwise be passed on through the driveline and cabin. Damping the movement of these springs are small friction washers fitted between the hub, retainer and adaptor plate.

Most factory cars come fitted with a sprung centre to aid engagement smoothness. These units have a series of small springs located radially around the hub that allow the clutch assembly to rotate slightly upon engagement to the flywheel. This helps to smooth out any torsional fluctuations and vibration that would otherwise be passed on through the driveline and cabin. Damping the movement of these springs are small friction washers fitted between the hub, retainer and adaptor plate.

Not surprisingly, a solid centre clutch plate doesn't have any springs fitted as the cushioning media (pictures of hybrid and full-face clutch above). And because there is no "give" upon engagement, its operation is much more ragged - making it less suitable for road use. The primary goal of a solid centre is to achieve the highest possible strength and durability under extreme conditions.

However, solid centres can sometimes be used conjunction with a "marcel backing" around the outer edge of full-face clutches. The "marcel backing" is a wavy material-lined backing on the clutch plate, which gets progressively compressed and released against the flywheel and pressure plate in relation to pedal movement. This design is sometimes used when some form of softening is required on the take-up of the pedal, and when space limitations within the hub prevent bigger hub springs from being fitted. The bigger hub springs are used when backing a high-torque engine.

The aforementioned Lotus Esprit uses this design to soften the operation of its factory multi-plate clutch arrangement. For a road car, this has a positive effect on clutch pedal feel between the engaged and disengaged positions.

Clutch Linings

There are four main types of clutch lining material available, with combinations of any two able to be bonded and/or riveted on either side of the clutch plate. Note that for each type of lining, aluminium or steel backings can be specified. This reduces the likelihood of high rpm clutch explosions, while the aluminium type backings have the advantage of reduced mass when compared to steel. The thickness of the clutch lining is also important. Thick linings offer longer service life and smoother operation, but aren't as suitable for race or competition applications. This is because their thickness doesn't offer quite as fast engagement, which equates to slower gear-change capabilities.

Organic

Organic (same material found in stock cars) is by far one of the best materials for clutches, in terms of engagement, and coefficient of friction (how well it will grab), and longevity. However, organic's worse enemy is heat caused by friction, which will tear it into shreds in the matter of seconds (problem found in our stock clutches). The car manufacturers pairs the clutch with a stiffer pressure plate with a higher clamp load that will reduce the friction and allow better "grabbing", as well as use of specialized brass-lined organic compound on the disc itself, which has brass weavings inside the compound, which will help keep the lining together and hold and transfer much more heat than conventional organic. This gives you the stock drivability characteristics, as well as take much more of a "beating". Organic linings are most frequently used on factory bog-stock cars as they are durable, smooth, easy on mating surfaces and cheap to manufacture. With a low coefficient of friction of around 0.32, they also require a fairly high clamping pressure.

Organic (same material found in stock cars) is by far one of the best materials for clutches, in terms of engagement, and coefficient of friction (how well it will grab), and longevity. However, organic's worse enemy is heat caused by friction, which will tear it into shreds in the matter of seconds (problem found in our stock clutches). The car manufacturers pairs the clutch with a stiffer pressure plate with a higher clamp load that will reduce the friction and allow better "grabbing", as well as use of specialized brass-lined organic compound on the disc itself, which has brass weavings inside the compound, which will help keep the lining together and hold and transfer much more heat than conventional organic. This gives you the stock drivability characteristics, as well as take much more of a "beating". Organic linings are most frequently used on factory bog-stock cars as they are durable, smooth, easy on mating surfaces and cheap to manufacture. With a low coefficient of friction of around 0.32, they also require a fairly high clamping pressure.

Ceramic

Of all types of linings, ceramics offer the highest coefficient of friction at around 0.48-0.55. This means they can be used with a lower clamping force pressure plate as the lining provides the grip. But because of this attribute, they cause a lot of wear on mating surfaces and shudder can be commonly encountered. Ceramics can take

Of all types of linings, ceramics offer the highest coefficient of friction at around 0.48-0.55. This means they can be used with a lower clamping force pressure plate as the lining provides the grip. But because of this attribute, they cause a lot of wear on mating surfaces and shudder can be commonly encountered. Ceramics can take  more heat than an organic material, but deliberately slipping the clutch tends to burn up the flywheel and pressure plate more than the lining. Made up from sintered bronze with ceramic material mixed in, there are a few different brands available that vary in their carbon content, but they are all mainly suitable for competition use.

more heat than an organic material, but deliberately slipping the clutch tends to burn up the flywheel and pressure plate more than the lining. Made up from sintered bronze with ceramic material mixed in, there are a few different brands available that vary in their carbon content, but they are all mainly suitable for competition use.

Kevlar

Kevlar, like organic linings, needs a fairly high clamping pressure to maintain grip. This is because Kevlar's coefficient of friction is similar, at around 0.30 and 0.35. Its biggest advantage over organics is its ability to withstand large amounts of heat. As a guide, up to 40-50% more can be endured, so long as it is being used in conjunction with a highly rated pressure plate. It also places virtually no wear on its mating surfaces. Many people (myself included) tend to want to go with the fancy "Kevlar", "puck" or "Racing" style clutches, thinking they will hold the power and last forever, however, their downsides include: poor drivability (rough engagement), nasty chatter, and ultimately: have worse longevity than even an OEM clutch.

Kevlar, like organic linings, needs a fairly high clamping pressure to maintain grip. This is because Kevlar's coefficient of friction is similar, at around 0.30 and 0.35. Its biggest advantage over organics is its ability to withstand large amounts of heat. As a guide, up to 40-50% more can be endured, so long as it is being used in conjunction with a highly rated pressure plate. It also places virtually no wear on its mating surfaces. Many people (myself included) tend to want to go with the fancy "Kevlar", "puck" or "Racing" style clutches, thinking they will hold the power and last forever, however, their downsides include: poor drivability (rough engagement), nasty chatter, and ultimately: have worse longevity than even an OEM clutch.

It's very hard to find pure carbon lined clutch pates for road going cars. And it's not an practical solution. Carbon as clutch lining is used only in very extreme environment, because of strong grip and harsh way it have to be used. Carbon ideal working environment is around 200-500°C. Carbon coefficient of friction is around 0.50 and 0.65. Must be used in conjunction with a very highly rated pressure plate. It also places virtually no wear on its mating surfaces, but carbon itself have a high wearing rate. Carbon composite lining is used for improved and maximum torque capacity, while a carbon composite puc style (segmented) facing is used for a positive engagement and maximum holding-capacity. On the picture you can see non-abrasive Feramic (Ceramic + Graphite "alloy") lining, giving you the ultimate coefficient of friction, yet non-abrasive on your flywheel surface. Very friendly but very high performance lining. Extremely expensive.

It's very hard to find pure carbon lined clutch pates for road going cars. And it's not an practical solution. Carbon as clutch lining is used only in very extreme environment, because of strong grip and harsh way it have to be used. Carbon ideal working environment is around 200-500°C. Carbon coefficient of friction is around 0.50 and 0.65. Must be used in conjunction with a very highly rated pressure plate. It also places virtually no wear on its mating surfaces, but carbon itself have a high wearing rate. Carbon composite lining is used for improved and maximum torque capacity, while a carbon composite puc style (segmented) facing is used for a positive engagement and maximum holding-capacity. On the picture you can see non-abrasive Feramic (Ceramic + Graphite "alloy") lining, giving you the ultimate coefficient of friction, yet non-abrasive on your flywheel surface. Very friendly but very high performance lining. Extremely expensive.

Pressure Plates/Clutch Covers

Pressure plates squeeze the clutch plate against the flywheel, so they're obviously largely responsible for the total amount of holding force generated. Car manufacturers usually aim to achieve a light clutch pedal weight to make driving easier, and they do this by using a fairly marginal pressure plate load rating. The good news is the clamping force of an OEM pressure plate can usually be increased by 50-100% by altering the fulcrum point and swapping or re-shaping the diaphragm. However, this amount depends on the location of the factory fulcrum point and the quality of the OE part can also be a concern. Some cars, such as Toyota GT-4 turbos, only have scope for another 10% pressure in which case an aftermarket pressure plate is usually required.

Pressure plates squeeze the clutch plate against the flywheel, so they're obviously largely responsible for the total amount of holding force generated. Car manufacturers usually aim to achieve a light clutch pedal weight to make driving easier, and they do this by using a fairly marginal pressure plate load rating. The good news is the clamping force of an OEM pressure plate can usually be increased by 50-100% by altering the fulcrum point and swapping or re-shaping the diaphragm. However, this amount depends on the location of the factory fulcrum point and the quality of the OE part can also be a concern. Some cars, such as Toyota GT-4 turbos, only have scope for another 10% pressure in which case an aftermarket pressure plate is usually required.

The maximum tolerable pedal weight is merely an individual opinion, but note that clutch cables (where fitted) can be stretched or overloaded if you go too far. On the other hand, cars fitted with hydraulic clutch actuation can be fitted with a pressure plate of substantially more load rating without excessive pedal pressure. Note that with a too highly rated pressure plate, it can also be possible to bend or break clutch forks and strain engine crankshaft bearings.

Flywheels

|

High performance Cast iron Flywheel |

|

Aluminium Flywheel |

The humble flywheel can be of significant importance in the overall clutch equation. The lighter a flywheel is the less moment of inertia it has. Lightened OE, light steel, or aluminium flywheels offer faster engine acceleration at the expense of idle quality, ease of take-off, steady state cruising and light-throttle smoothness. The good news for the clutch is whenever the pedal is engaged, the rotational difference in speed between the clutch and the lightweight flywheel can be quickly equalized. And the faster this speed stabilization occurs, the less accompanying clutch slip there is.

But problems can arise. For example, when aluminium flywheels are combined with ceramic clutches, it is possible for some microscopic aluminium particles to be lost to the harsh clutch lining. To combat this, some companies now heat-treat their flywheels prior to installation, and some have a replaceable steel heat shield inset in the mating faces.

On the other hand, really hard-launching cars might need to opt for an extra-strong flywheel such as a hardened billet steel or chromoly item - as OE and some lightweight flywheels have been known to disintegrate off the starting line. And factory cast flywheels that have been lightened are notorious for failing, so be careful.

Some Typical Clutch Problem Solutions

All in all, if you want to keep your stock drivability and characteristics, yet wanting the clutch to hold more power than a stock clutch, the Organic is definitely the way to go. The standard Organic clutch will be paired with a pressure plate that will hold approximately 220 m/kg (325ft/lbs) of torque, while stiffer pressure plates are also optional. Will work with both OEM and aftermarket flywheels.

If we are talking about clutches, I like to use the word "practical" as opposed to "best". There are clutches out there that will hold 350, 400, or even 700 m/kg (500, 600, or even 1000 ft/lbs) of torque, that use a 6 or even 3-4 puck discs. You can do all wheel drive launches all day long until your car blows up and clutch will not break... but it will also drive like crap for everyday driving. Would you call this the "best"? For drag racing, yes... for practical daily driving, no. Many think that because most of these "high power" clutches hold so much power and can take all this abuse, that it would also "last longer". But truth of the matter is: it's FALSE. Having less surface contact area will allow the clutch to "grab" better, making it a "on/off" clutch and will not "slip", but less contact and surface area also means less material being used, thus making the longevity of the "race/puck" discs horrible.

There are also "street" clutches that will drive like STOCK, using organic linings as opposed to the heavy duty Kevlar and ceramic, but organic will easily burn up if you decided to do that 6000rpm drop. Organic linings last the longest, but its biggest weak spot is heat. And when clutch is slipping = heat.

Taking these factors into account, we now need something that gives us the "real world" daily driver attributes (i.e. smooth engagement, longevity), yet also take a routine beating on track days. These are attributes that make suit the "practicality" needs for a clutch on the highway and racing track speed days.

|

"OFE" (Organic/Feramic Element) Clutch |

As a result, I recommend an OFE unsprung stock organic clutch disc, lined with a brass-weaved organic lining, as well as a feramic compound (graphite + ceramic)...thus the name "OFE" (Organic/Feramic Element).

The brass weaving on the disc allows the organic material to maintain it's favorable characteristics, but will allow it to take much more heat so that it wont "tear up into shreads" after some launches. The Feramic element allows a higher coefficient of friction (more "grabby"), yet the graphite element inside the Feramic will make the element less abrasive (graphite wears down on your flywheel like pencil lead) so your flywheel will not wear down as quickly.

To top it off, what prevents "slippage" during hard driving is the pressure plate. A stock OEM pressure plate has ~680 kg of clamping pressure...and the more clamping pressure, the stronger it will "clamp" the clutch disc and keep it from slipping. The OFE uses a ~800 kg pressure plate which will hold ~220 m/kg of torque. The clutch drives and engages like stock, and will take a hard beating and not smell like burnt ashes (like your OEM).

I am conveying this through my good and bad experiences in finding the "best" clutch for my Audi A4... I've used heavy duty "race" clutches, and I've also used OE-style "driver friendly" clutches as well, and after going through 4 clutches on my A4 and changing them out myself every time to see my "damage", I can personally recommend the OFE...for it being the most "practical" for your needs.

With the above information in mind, here are some examples of some typical clutch upgrade scenarios and what would be the recommended solution:

Scenario 1 - A mildly modified 4WD turbo owner wants to spend as little money as possible and is wanting a long clutch life, with near-factory smoothness but is able to withstand occasional hard launches.

Solution - Retain standard cast flywheel, re-line standard full-face clutch with Kevlar lining or organic OFE lined plate, and fit a more serious aftermarket pressure plate.

Scenario 2 - A Suzuki Swift GTi owner wants to achieve a more positive clutch pedal engagement and less chance of slip.

Solution - Fit a Kevlar or organic lined OFE hybrid-type sprung centre clutch plate, along with a high clamping pressure plate and standard flywheel.

Scenario 3 - Owner of a regularly drag-raced 400-500hp Holden Commodore wants to eliminate any chance of slip, maintain maximum service life and isn't too concerned about engagement smoothness or cost.

Solution - Option one would be a single plate clutch in a large-as-can-fit (26 centimeter) diameter with a heavy-duty pressure plate. A choice of linings would be available to suit. The second option would be a twin-plate clutch, also with a choice of linings but a medium-duty pressure plate will suffice.

To improve your knowledge about Formula 1 car clutches, check my article here

Congratulations!

You should now all be able to speak authoritatively on the topic of clutches, and know what to do if your own car's clutch packs it in.