Side skirts

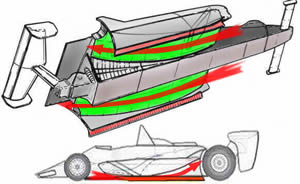

Side skirts are used to reduce the amount of high pressure area on the side of the car to go under the car from the sides. If an air splitter is used, air under the car is at a low pressure, which causes the higher-pressure air on the outside and on the sides of the car to come rushing in diminishing ground effect and downforce.

The effectiveness of the skirts depends primarily on how close to the ground the lower edge can be maintained. That edge should be less than a 2 centimeters from the ground, otherwise the skirts' effectiveness diminishes rapidly as the gap increases.

There is another aero device which helps to prevent air to flow underside of the car. Name of this device is front vortex generator. Canards, together with vortex generators, generate strong vortices that travel down the sides of the car and act as a barrier. If the generators are positioned correctly, these strong vortices act in way to keep high-pressure air around the car from entering the low-pressure underbody region, thus maintaining more downforce.

But you have to know that on road going car side skirts are a cosmetic addition to your performance looking vehicle. Taking the time to buy the correct skirt and planning for the appropriate add-ons ahead of time, and that will make your side skirt purchasing experience less stressful. Body kits for road going car can dramatically alter the appearance of the car and sometimes for the better! They can sometimes also improve the handling giving enhanced aerodynamics. If you are buying side skirts for your road going car, try to find model of side skirts on which rear side of the skirts is fitted with vents in order to ensure that the rear brake disks are cooled down easily.

Low skirts and sills can increase cornering speeds but a badly fitted kit can cause grounding on speed bumps or dramatically effect the cooling of the engine for good or for bad – check the temperature gauge after having a kit fitted and ensure that the engine is not running hotter.

The kits should usually be fitted with a stiffer suspension to maintain the ground clearance of the car but this can really kill the around town usability of a car.

Side skirts in Formula 1

To know more about ground effect, check out my article here.

Ground effects were first implemented in Formula One by Lotus designer Colin Chapman. 1970s that is – the teams using Cosworth power plants were trying to find a viable solution to make up for the loss in performances as compared to richer F1 manufacturers. And maximizing the used power of their engines through some clever aerodynamics was the only way they knew how.

Side skirts in yellow on Lotus79b ground effect car

The term “ground effects” was given to the innovatory aerodynamic package created to set up a sucking-like effect under an F1 car. What that means is that F1 car were practically “glued” to the track through some rather interesting under-car styling, leading to incredible cornering speeds.

The principle behind the ground effect is quite simple. What the F1 engineers tried to obtain was a low pressure area beneath the car which, combined with the high pressure above it, would create a tremendous force pushing the car downwards. In Formula One, the solution found by Chapman was to create a revolutionary design for the car's underside. It's curved styling – like inverted airfoils – allowed the air that entered the car's underbody to accelerate through a narrow mid-section between the car and the ground, therefore creating a low-pressure sucking section.

However, the aforementioned design was not enough to create the expected ground effect, as the air coming from both sides of the car (from underneath) would have ruined the entire vacuum effect. In order to prevent that from happening, the Lotus engineers fitted the cars with flexible side skirts, therefore sealing its underside section. While initially built out of brushes or plastic, the best solution proved to be rubber-build skirts, as they didn't wear out during races.

Colin Chapman – with the help of fellow engineers Peter Wright and Tony Rudd – developed the entire concept through the 1976 season and eventually implemented it on the famous Lotus 78 (also known as the John Player Special Mk III) starting the 1977 Argentine Grand Prix.

Chapman didn't understand all effects caused by inovation, and like all starts, however, the 1977-build Lotus 78 suffered from several reliability problems. First of all, the airflow coming from beneath the car interacted with the large rear wing, causing plenty of drag at high speeds. What practically happened was that all the advantage gained at corners was counteracted by the poor performances of the Cosworth engines in straight line. The next step, made by Ford, was to try and improve the performances of their V8 power plant. However, race to race, adjustments on the engine often led to poor reliability, and the season ended with no less than 5 engine failures for 2nd placed Mario Andretti.

Due to the increased level of cornering speeds in Formula One during the 1979 season – which led to lap times some 6 seconds quicker than in previous years – the FIA decided to introduce a mandatory flat underside and banning the side skirts for the F1 cars.

Back to the top of the page