Transmission

Just like in your family road car, F1 cars have a clutch, gearbox and differential to transfer the 800 bhp into the rear wheels. Although they provide the same function as on a road car, the transmission system in an f1 car is radically different.

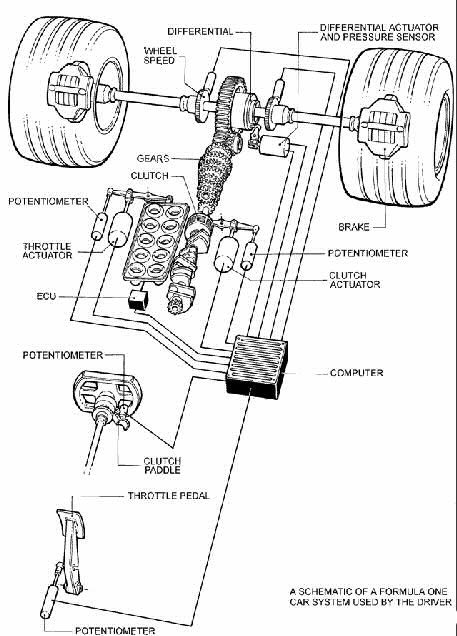

A good engine must be installed well to perform to its ultimate ability, and it must output its power to the wheels in the best way possible. The engine is connected to the flywheel, which is linked to the drive shaft via the clutch plates. The drive shaft goes into the gearbox, which is connected to the axles (and therefore the wheels) through the gears and differential.

Having explained how the gearbox works in my article, the next thing to consider is how to change between gears. This is done using the clutch. But why? Well, with the gear wheel on the end of the drive shaft rotating in the gearbox, it is not going to be easy to move it through the gears to meet up with another gear. Any attempt to do so will result in that annoying, grinding noise heard all too often from a poorly driven car! That noise is the noise of the rotating gear wheel on the drive shaft grinding against one of the gears in the gearbox - carry on with that, and you're going to be left with a gearbox full of metal shreds! Or worst!

This is why the drive train in a car incorporates a clutch. In F1, they are multi-plate designs that are designed to give enhanced engine pick-up, and the lightweight deigns with a small diameter mean that they have low inertia, allowing faster gear changes. Flying wheel on F1 car is just 10 centimeters in diameter. The drivers do not normally use the clutch manually, apart from moving off from standstill, during pit stop and in case of emergency or spin. They simply press a gear change selector lever behind the wheel to move to the next ratio. The on-board computer automatically cuts the engine, depresses the clutch and switches ratios in the blink of an eye.

In the world of the F1 semi-automatic gearbox, of course, there is no need for the driver to even think about this – everything is electronically controlled! All the driver is required to do is to pull paddle when he wants to change up or down a gear, and the electronics controlling the gearbox and clutch do the rest. The advantages here, over and above the fact that the driver can keep his hands on the wheel at all times, is that the whole process can be done in a split second (much quicker than a manual clutch could be operated) and also that the wear on the clutch pads is less because it is never held half-on, and so this increases reliability.

The engine and transmission of a modern Formula One car are some of the most highly stressed pieces of machinery on the planet.

Traditionally, the development of racing engines, transmissions and the rest of F1 car has always held to the rule of the great engineer Ferdinand Porsche who stated that the perfect race car crosses the finish line in first place and then falls to pieces. Although this is no longer strictly true - regulations now require engines to last five race weekends, and gearbox's four - designing modern Formula One engines remains a balancing act between the power that can be extracted and the need for JUST enough durability.

The start phase in Formula 1 is very important. Beginning and first highlight of every race. Decisive fractions of a second. So much is at stake during the first few hundred meters of a Formula 1 race today that some of the most sophisticated and secret engineering on the cars is been devoted to help a driver during those first couple of seconds, during which he attempts to get his car off the line and up to speed quicker than those around him on the grid. The prize was the order of cars into the first corner, which in today's racing so often dictates the order for the rest of the race. Of course, that was until year 2007!!! Previously the drivers could rely on highly sensitive and fast electronics during this critical phase - from 2008 no longer. With effect from this year, the regulations forbid the use of ANY start electronic assistance and traction control in race phase. With common ECU this is easily controlled by FIA. Sensitive handwork during the start is again in demand. And that should be taken literally, because in the F1 the commands to the gearbox and clutch are distributed by means of a steering wheel mounted paddles. Transmissions may not feature traction control systems, or devices that help the driver to hold the clutch at a specific point to aid getaway at the start of the race.

After abolishing all electronic help during the start phase Thomas Rudolf, engineer for clutch systems at ZF Sachs Race Engineering explained "We see the return to handwork from a technical view point with mixed feelings".

The ZF Sachs AG motorsport department equips the Formula 1 teams of Ferrari, Honda, Toyota and some other teams with clutches and shock absorbers.

With electronic control and help, the clutch got rid of surplus power with slips between carbon clutch plates. As a result, this important interface in the drive train was subject to extremely high loads, for up to two seconds and in exceptional cases even up to ten seconds and heated to temperatures in excess of 1000 degrees Celsius.

The engineer explains why: "In contrast to a normal car with a clutch pedal, the Formula 1 driver doesn't feel a pressure point with his paddle. He must REMEMBER in which paddle position the gear is engaged. It is a balancing act. Even top drivers like Michael Schumacher can slip the clutch for only a maximum of half a second as to help to pull away. This is not enough, and is only a quarter of the time that the electronic help function for pulling away demanded."

A few key figures illustrate these extreme loads that impact on the F1 clutch from ZF Sachs weighing no more than roughly 860 grams: the diaphragm springs apply 1.6 tons of pressure to the three clutch plates, and the tiny 100-millimetre titanium housing withstands temperatures of up to 700 degrees centigrade.

Does the new regulations therefore guarantee an easier time for the clutch? No. Because, where the human element is involved mistakes happen. If a driver misses the pressure point and releases too fast, the engine could stall, he disengages the clutch again, lets the engine revs skyrocket and tries to reengage the clutch again. Often, the whole process is repeated several times. As a result even higher loads and temperatures can occur. Even if such mistakes are not the rule, engineers who construct the clutch must make provision for them. That's why they have refrained from reducing the reserves released through the abolition of the electronics.

In fact the Sachs Formula 1 clutch of 2008, at the same overall dimensions as its predecessor, is even more efficient. The technicians reduced the clutch hub size of previous successful model, but anyway they gain more room for the stressed carbon disc friction faces. The diaphragm spring, which clamp the friction plates with a force of 1.6 tones, are produced from special steel alloy resistant to temperatures of up to 700 degrees Celsius. Also the tiny titanium housing with a diameter of around 100 millimeters is, thanks to an even further optimized machined contour, more robust. Sachs expects the component longevity to have increased by a factor of three. The housing is particularly stressed by engine vibrations. "Although the engines must last a two race-weekend, the relevant key data for us remains almost unchanged. The power units still rotate at 18,000 rpm and are actually lighter rather than heavier. And the lighter an engine is, more it vibrates, which wears out the clutch housing", explain Sachs engineer.

The new gearboxes that have to last for four races also have no influence on the clutch. From the technical point of view Formula 1 racers do not require a clutch to shift in the higher gears. The loads resulting from this have already been taken into account for years.

For safety reasons all cars must have a means of disengaging the clutch that is operable from outside the cockpit by marshals. This control is usually situated just ahead of the cockpit opening and is marked on the car's body by a red letter "N" within a white circle.

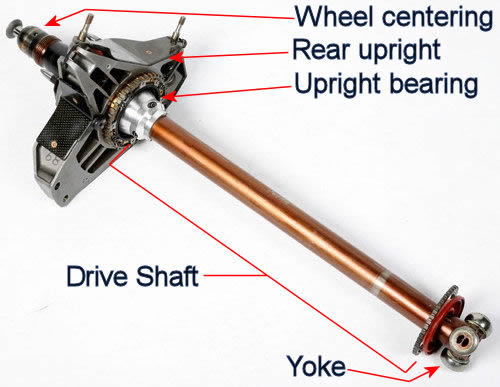

When you hit the throttle, the engine spins the flywheel, as we explained before. The flywheel transfers energy to the gearbox that is transferred to the differential, who's duty is to spin the tires putting the power to the ground. One very important part of the machinery lay in between differential and the wheel. The drive shaft, some time called half shaft, is only link between the gearbox/differential and the rear wheel. The problem is that the common view about the drives haft is "it's a simple link". The fact is, while you can't gain horsepower through the drives haft, you can certainly lose it. Drive shafts are carriers of torque: they are subject to torsion and shear stress, equivalent to the difference between the input torque and the load. They must therefore be strong enough to bear the stress, whilst avoiding too much additional weight as that would in turn increase their inertia.

To allow for variations in the alignment and distance between the Differential and upright, drives hafts must incorporate one or more universal joints. In Formula 1, there is only one joint called yoke, slip yoke or slip joint, located on one end of the drives haft, connecting point between differential and drives haft. The slip-yoke and the pinion-yoke take a lot of abuse in a high-performance application. These are the physical connectors to the transmission, drives haft, and differential. All torque and power is transferred trough this joints. In most applications a cast pinion-yoke is usually strong enough to handle more than 800 hp. That number has some fudge room, though, as a lightweight Formula 1 car with 800 hp will usually put less strain on the yokes than a 2 tonne car with slick tires and 500 horses. When the slip-yoke fail, it can wipe out just about everything it could in his vicinity.

What the drives haft is made of is just as important as its length and diameter. Some time ago, drives haft use to be made of chrome-moly or lightweight aluminum. Chrome-moly, is the strongest possible metallic material and usually seen in Pro Stock cars. Chrome-moly steel tubing can be heat-treated as well, raising the torsional strength 22 percent and increasing the critical speed 19 percent. The problem with steel is it is heavy, which increases the load on the drivetrain. Aluminum is probably the most common performance drives haft material.

The lightweight aluminum shaft reduces rotational mass, freeing up horsepower from the engine and reducing parasitic loss. An aluminum drives haft will support 900 and up to 1,000 hp, making it a great lightweight choice for most muscle cars. However, it is not as strong as steel, so some custom drives haft shops do not have twist guarantees on aluminum drives hafts.

Modern Formula 1

use carbon fiber. Carbon-fiber tubes are the most expensive, but they are also the most efficient. When you are looking at power figures up to 1,500 hp, carbon fiber is a great choice. Carbon-fiber drives hafts are not only strong, but they also have a surprisingly high torsional strength, resisting twisting and reducing the shock factor on the rear end. Carbon fiber also has the highest critical speed module of elasticity, meaning the shaft won't flex at slower speeds, unlike other material components. Coupled with the highest critical speed and the light weight, a carbon-fiber drives haft can free up some horse power over aluminum, and especially over chrome - moly tubing. When winning is everything, that might make the difference.

What is most often cause of drives haft failure is reaching critical speed. All drives hafts have a critical speed. Critical speed is the RPM at which the drives haft becomes unstable and begins to bend into an S shape. The longer and smaller diameter a drives haft is, the lower its critical speed. Critical speed is felt as excessive vibration that will cause the unit to fail. To calculate the critical speed, the length, diameter, wall thickness, and material module of elasticity must be known. There is a complex formula to calculate the critical speed for every drives haft. The module of elasticity of the shaft material is an important part of the equation. For steel, the basic MOE is 30, aluminum is 10, and carbon fiber depends on the manufacturing processes used, so no numbers are available.

Back to the top of the page