Flow Visualization Paint

or Flow-Viz

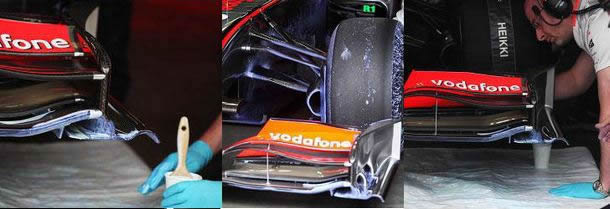

McLaren using Flow-Viz paint at preseason testing at Jerez 2011

When McLaren ran “Flow-Viz” paint for first time on their car in testing last year (2010), the F1 world sees it for the first time. But in fact, teams have been using this solution for years in privacy of their wind tunnels to show surface aerodynamic flows, but this year (2011) even Renault, Lotus, Red Bull and Ferrari bring it to the track and start to use it openly and a large amount of green, blue or white fluid was splattered all over the cars.

But there is no mystery. That was a special liquid placed onto the car to help with the aerodynamics. Engineers know that work in wind tunnel and CFD programs can give you great results, but nothing can compare with real life situation on track. To better understand air flow over aero surfaces in this real life situation, teams employ what is call „Flow-Viz“ paint, or „Flow-Visualization“ paint. Details like direction and attached\non-attached flow can be observed. But this is only surface airflow and this is not the entire story when it comes to aerodynamics, so “Flow Viz” is only one solution for measuring and observing aero on track.

McLaren engineer applying Flow-Viz paint on front wing

Basically, they put it on, and before it gets chance to dry the car is flying around the circuit. As it does so, the air flow across the car moves the paint around, where it subsequently dries and shows detailed air flow patterns across the car. It is to confirm wind tunnel and CFD findings. Formula 1 teams don't like to use this method very often because in this way all other teams can see real situation on your bodywork air flow management. If team have a problem with aerodynamic components, everybody will se it, if there is some secret solution in airflow management, everybody will know it. It's enough to take photos of ones car and analyze it with your aerodynamicist and here you are. Basically, my opinion is that if team resorting to flow visualization paint so openly and in front of so many spying eyes leads me to think they're really having some problems with their aero, or there is some fundamental work to be done for further understanding in aero development.

|

McLaren during F-Duct testing 2010. You can clearly see slot in rear wing flap on picture above, and air streams around it. |

But what is this paint?

Paraffin-based light solution applied it to the car. The solution is light enough to flow over the car, drying quickly to determine the airflow over the bodywork.

A surface of a component of the car is coated with a pigmented (preferably a contrasting phthalocyanine) or transparent oil based paint of non-gelling characteristics, and with a specific viscosity chosen in way that paint will not spill or move when car is stationary. Sometime, if team need to make longer stint with “Flow-Viz” applied, they can apply additional layer of wetting agent to prevent to fast drying of paint. Particles of a dry phthalocyanine dye are then uniformly sprinkled onto the coating of the paint using a dry brush or an air blower depending on the accessibility of the surfaces under test. Dye particles must be soluble in the oil based paint. Optionally, wetting agent such as Linolic Acid can be applied to ensure cohesion of the oil based paint and dye. After that you need to pass an air flow over the component, mean, you go out and drive your car.

A surface of a component of the car is coated with a pigmented (preferably a contrasting phthalocyanine) or transparent oil based paint of non-gelling characteristics, and with a specific viscosity chosen in way that paint will not spill or move when car is stationary. Sometime, if team need to make longer stint with “Flow-Viz” applied, they can apply additional layer of wetting agent to prevent to fast drying of paint. Particles of a dry phthalocyanine dye are then uniformly sprinkled onto the coating of the paint using a dry brush or an air blower depending on the accessibility of the surfaces under test. Dye particles must be soluble in the oil based paint. Optionally, wetting agent such as Linolic Acid can be applied to ensure cohesion of the oil based paint and dye. After that you need to pass an air flow over the component, mean, you go out and drive your car. As a flow of air is passed over the solid component, this causes the dye particles to move across the coating of the paint under the influence of the air flow. The dye particles that come into contact with the coating of the paint, dissolve in the same time in the oil as they are moved, to leave a trail on the surface of the coating. This results in a reduction in the size of the particles due to their dissolution. Air flow produces a pattern of contrasting trails on the surface of the coating which permanently records and highlights the fluid flow distribution pattern for later analysis.

As a flow of air is passed over the solid component, this causes the dye particles to move across the coating of the paint under the influence of the air flow. The dye particles that come into contact with the coating of the paint, dissolve in the same time in the oil as they are moved, to leave a trail on the surface of the coating. This results in a reduction in the size of the particles due to their dissolution. Air flow produces a pattern of contrasting trails on the surface of the coating which permanently records and highlights the fluid flow distribution pattern for later analysis.

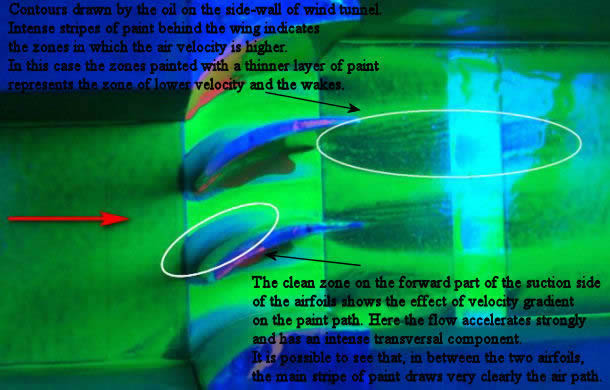

Comparison of the relative movements of the dye particles provides an indication of the relative strengths of the air flow acting on the surfaces of the component under test. Aerodynamicist can see the contours drawn by the oil on the side-wall of rear wing support or wing element itself. The intense stripes of colored oil behind the wing cascade indicate the zones in which the velocity is higher.

This happens because the oil, coming from upstream, is feeding the wing element section downstream. In this case the zones painted with a thinner layer of oil represent the zone of lower velocity and the wakes. The clean zone on the forward part of the suction side of the airfoils shows the effect of velocity gradient on the paint path. There the flow accelerates strongly and has an intense transversal component. It is possible to see that, in between the two airfoils, the main stripe of oil draws very clearly the air path.

Looking at the oil stripes on tested elements it is possible to see if they follow trajectory in accordance with the CFD simulations or wind tunnel test.

Picture down was taken on Saturday morning practice at Korean Grand Prix 2011 as Ferrari tested its new front wing planed for next season, with a load of aero paint sprayed over it.

Look closely at this rear brake duct on the new Marussia car during preseason test 2013 in Jerez. What you see painted is what is called a “cascade”, which is a multi element piece on the brake duct which is an important downforce making device close to the rear wheel.

Look closely at this rear brake duct on the new Marussia car during preseason test 2013 in Jerez. What you see painted is what is called a “cascade”, which is a multi element piece on the brake duct which is an important downforce making device close to the rear wheel.

You can see the flow structure; the lower lines aren’t too bad, but as you get to the upper elements the flow moves inboard and separates at the top edge and on the top element the flow has broken down completely.

This cascade isn’t working properly; the geometry is too aggressive and the imperfect flow lines are a clear indication to the team’s engineers that they have work to do in the wind-tunnel. It’s back to the drawing board on this piece for Marussia. Lines of the paint must be perfect and air attached as it works its way all over tested piece and this is what engineers want to see when they analyse the flow structure. It means that the element is doing its job in line with expectations.

Ferrari SF15-T rear wing with flow-viz applied