What is the most important part

of a racing car?

Michelin's top engineer reveals some of the secrets of racing rubber and understanding tires

'What is the most important part of a racecar?' asked the university lecturer. 'The aerodynamics!' cried one student, 'the engine!' cried another. To both responses the lecturer slowly shook his head. 'The most important part of a racecar is the tires,' he revealed. An over simplification perhaps, but true none the less. Getting the best out of a given tire can be the difference between winning and being lapped, and this has never been so true as it is now with the seemingly unstoppable rise in control tires and spec series. It is worth noting here that no major open-wheel racing series anywhere in the world allows completely free tire choice these days and in fact, the only place teams do still have a true choice is in endurance sportscar racing. So it's no surprise then that you will find Michelin at its most active in the paddock of a Le Mans Series race, one of the last series to still run many different chassis, engine and gearbox types, as well as allowing constant development.

'When we work with a customer chassis manufacturer like Lola or Courage, they don't ask us to make a special tire for their cars,' explains Michelin's competition manager for four-wheel activities, Matthieu Bonnardel, 'instead they try to design the car to suit the tires. So they look at what tire sizes we have and get some physical data, then they get data from us on the characteristics of our tires, which will help them optimize the aerodynamic design and the suspension. Then when the car is complete they can bring it to our test track in France where we can gain real understanding of the car's behavior - the downforce for example. We have a few devices that allow us to take a closer look at what happens on the car, as well as on the tires, and the teams like that.'

One thing that is sometimes overlooked by chassis designers is that the tires are a critical part of the machine, not just something to bolt on and go racing with. Some acknowledge that the sidewall of a tire has an effect on that corner's spring rate and damping, but Bonnardel reveals that the situation is far more complicated than that.

'There are a lot of complex things going on in a tire when it's running on a track. For example, the tire spring rate does not just depend on the sidewall - that would be too easy - the sidewall construction is a factor, but so are many other things. It can vary with tire type, size, temperature, load and pressure. It will even change depending on how much camber a car is running. The more you run, the more it leans on the shoulder and that puts more load into the sidewall. A tire that is overloaded has less spring rate than a tire that is not loaded, for example. And finally, spring rate changes with speed, so one tire does not have one spring rate, it has billions of spring rates in the same tire. We know a basic rate and communicate that to our partners, of course, but we also have to communicate the range of different rates and how it changes through the various usage of the tire.'

Even if spring rate is considered at the design phase of the car there are a number of other complex interactions that need to be considered, as Bonnardel reveals: 'Spring rate is just one thing though. It gives you a loaded radius, that tells you how high the car will be, so it's crucial when you design the suspension that you know that figure, though some of that is influenced by other factors, too. For example, you need to take into account the expansion of a tire as it changes shape depending on the situation - downforce and car weight try to reduce the tires' radius, but speed is trying to increase it. In fact these two situations sort of offset each other, because as the speed drops so does the downforce.'

Teams also benefit from the tire developers know-how, as they too must consider some of the trade offs on a race-by-race basis. 'When I started to discover the world of tires, I found it very odd and I believed some very stupid things,' says Bonnardel. 'For example, when you have a tire with a two metre circumference, I believed that when I rolled through 360 degrees it would have travelled two metres. Of course, if you take the tire on its own it will, but when you load it with 500kg and start again the distance it travels might be 1.8m. I thought, "what's going on here?" but I soon realized that the rolling circumference changes with load, and that changes with speed by a differing amount depending on the car. The amount it changes is very important for the gearbox, so teams ask us to give them a sheet with all this data on it to help tune the aero and find the right gear ratios.' In fact, so crucial is this information that some teams work directly with the track support engineers and the tire companies to work on maximum lateral force, braking force and the combined forces for simulations.

'Are we active in the design of the car, where the engine goes, what the inertia should be? No. What we do is about optimization,' Bonnardel continues. 'We give out ideas about how to optimize the tire, but there's a lot more factors in making a car go fast - like making sure the downforce is at its maximum. If you did everything to the ideal for the tires and optimized the contact patch you would lose all the downforce, as the car's floor would pitch around and not generate it so well. But if the team set up the car to keep the ride height perfect the car would be so stiff the driver wouldn't be able to see and the tire wouldn't work well, so there's no point either. There is an optimum point, but normally that is more toward getting the best out of the tires than the aero.'

However, there are some teams, usually better funded or works outfits, that liaise with the tire makers at a much earlier point in proceedings. 'Some partners involve us from the birth of the project, then ask us how we would like to see the car designed which, in the end, should be the most efficient car possible. Recently I had a meeting with Hughes de Chaunac about the new Courage-Oreca LMP, and we looked at how we could be working to get the tires working at 100 per cent of their potential.'

Whatever way teams work with tire makers, it seems that the old adage is still true - the most important part of a racecar is its tires.

Michelin engineers explain the basic science behind what makes a tire stick to the road.

Without grip, Endurance cars simply wouldn't work. They would be incapable of going in a straight line, let alone braking. A racing car's every movement is conditioned by the level of grip generated by its tires, its only points of contact with the circuit. Polymers, sulphur bonds, moduli, stress frequency. All are a matter of routine for the specialists who understand the essence of grip. They are fairly simplistic terms, however, within the realms of an art that often borders on alchemy. Tires stand on a tread that contains elements of rubber, among other things.

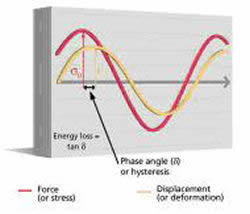

These rubbers are visco-elastic materials (the kind of thing you'll also find in chewing gum, for instance), which gives them a level of deformability that lies somewhere between a viscous liquid (such as oil) and a flexible solid (like a spring). While a spring changes shape instantly - and proportionally - to an applied force, viscous fluids behave differently: the faster you attempt to drive a piston into an oil-filled cylinder, the greater the degree of resistance. And when you first start to exert pressure on the piston, there will be a delay before there is any perceptible movement. The liquid's viscosity is caused by friction between its constituent molecules.

Rubber used in the tire-manufacturing process comprises a blend of polymers - long chains of molecules that spontaneously adopt a spherical form and knit themselves together. To create a tire, these rubber structures are vulcanized - cured in an oven after the addition of sulphur. The baking process generates the creation of numerous sulphur bonds between the polymer chains.

The level of viscosity varies according to the selected polymers (polyisoprene, polybutadiene, butadiene styrene, etc.) and to the number of sulphur bonds that have been generated during vulcanization. As a function of these parameters, the final compound might be relatively soft (which will give it a lower "modulus" - a coefficient that reflects a particular substance's specific properties) or relatively hard (which generates a higher modulus).

In order to optimize grip, tire tread components are designed to combine a median modulus (acceptable suppleness) with maximum viscosity.

For any given compound, the problem is that these two characteristics vary according to the intensity of the tiers' workload (the frequency of contact with the track, a corollary of the car's speed) and the prevailing temperature. These two criteria have directly opposing influences.

If the contact frequency is too high, the rubber compound stiffens (to the point that it becomes brittle) and loses all viscosity. Temperature has the opposite effect. In cool conditions, the compound is stiff and brittle. As the temperature rises, in contrast, it becomes soft and supple.

There is consequently an inversely proportional relationship between an increase in rubber temperature and a reduction in the frequency of the loads to which it is subjected. At low frequencies, increasing the contact by a factor of 10 has the same effect on the behavior of the rubber as a 7 to 8°C drop in temperature. When it comes to making a tire, it is important to select tread compounds that remain suitably supple and have a higher level of hysteresis according to the workload, characteristics and ambient temperatures at each circuit.

Two distinct phenomena govern a tire tread's level of grip The essence of grip can be found in two mechanisms that intervene when a tire is sliding on the track:

Indentation: this is where the tire deforms as it slides across small bumps in the circuit. The compound's supple characteristics allow it to mould its shape to accommodate such surface imperfections. When the rubber slides on the track, it deforms in a flowing manner (thanks to its viscous properties). Having clipped a bump, the rubber deforms and does not immediately regain its original shape once it passes over. By dealing with surface fluctuations in a dissymmetrical manner, the tire builds up a degree of force that counters any tendency to slide.

For this type of indentation to occur, the track has to feature small ripples that might be anything between a few microns or several millimeters in size. Even when it rains, the phenomenon works in exactly the same, efficient manner. Grip is a consequence of molecular contact that can be measured to an incredibly small degree - about one hundredth of a micron - and is amplified when a car slides.

Grip is created by molecular interaction at the point of contact between a tire and the track. When the tire is moving, part of the tread is physically touching the surface at a given point and its molecules extend until contact is broken. The rubber's molecular chains are subjected to a constant cycle of extension and release that creates a visco-elastic effect inside the tire (generated by the friction of the molecular chains within the carcass). This can multiply the force of contact by a factor of anything between 100 and 1000, according to ambient temperature and the speed at which the rubber is sliding on the track.

To grip, you need to slide (just a bit).

With each of the aforementioned mechanisms, the reactive forces that govern deformation and molecular liaison would be purely vertical, rather than tangential, if the tires were not sliding to a degree on the track surface. You have to provoke the beginnings of a slide to generate counter-sliding forces that enable a car to stick to the track. At a microscopic level, these phenomena of grip are all the more astonishing when they happen in incredibly short bursts: for a racing car travelling at 300 km/h (186 mph), the molecules within a tire's contact patch touch a point on the track for two-hundredths of a second. The molecular rubber generates surface grip - that little bit of black magic - at lightning speed.

Key points to remember

Rubber is a visco-elastic material whose behavior can be symbolise as a cross between that of a spring and that of a piston. It has reversible deformability but, once its shape has altered in a particular direction, it doesn't resume its original form until a period of time has passed. It's a retardation of the effect when forces acting upon a body are changed, or hysteresis. This phase differential is accompanied by a loss of energy.

To know more see the articles:

Tires

Using Tires

Tire Warmers