KERS

To learn more about new 2014 rule change, new Formula 1 Power Units and new ERS System follow this link.

This article was born at the beginning of 2008, before anybody know what will be final decision of Formula 1 teams, what type of KERS will be used. Everything was still in phase of preseason speculations. And a lot of things are gone differently. I will not change it, it will stay as curiosity to show how things can change in a few months. Most famous was my prediction "like electrical engineer" ;-)) . Ooo, how I was wrong!!!!

"Renault, Ferrari, BMW, RedBull Racing and some other teams decided to go with Generator - Batteries - Electric motor combination. If you ask me, like electrical engineer, my opinion of this combination is not ideal. Batteries are weak link in this chain. Battery technology is still not efficient enough, and weight to Amper/hour (capacity) ratio is still on negative side, and for sure they will need additional water or air cooling. Spill of acidy substances during accidents can be very dangerous. Packing of enough batteries and their shape can be a problem. Lithium polymer batteries can be packed at any shape, but technology is still very young and expensive even for F1. Think of price of the battery for your mobile phone. So small and so expensive. I think that much better solution is capacitor."

BTW, batteries are still the weak link. But all teams decided to go with it because of easy packaging, and lithium polymer batteries can be molded in any shape. And price...? Who care?

Anyway, in red color are corrections, what actually happened in real life!!!!

With the introduction of KERS, Kinetic Energy Recovery Systems, Formula One is to go innovative again.

The principle of the system is to use surplus energy that is created by a F1 car while decelerating, into a propelling force. According to the FIA, a kinetic energy recovery system is 'a system that is designed to recover kinetic energy from the car during braking, store that energy and make it available to propel the car'. So, regenerative braking using surge power units, is about to become legal in Formula One. FIA's original proposal to limit the weight of the 'energy recovery device' was 20kg. The good news is that there are no limits, maximum or minimum, on the weight of the surge power unit (FIA keeps referring to it as 'the KERS').

Presumably, the main reason the FIA proposed a 20kg limit was to keep performance limited. This has now been achieved by limiting power output of KERS unit. The limit is set at 60 kilowatts, roughly 80 bhp. The key new clause in the 2009 regulations is as follows:

5.2.3 The maximum power, in or out, of any KERS must not exceed 60kW.

Energy released from the KERS may not exceed 400kJ per lap giving the driver an extra 80hp over a period of 6.67 seconds. Energy can be recovered only during deceleration.

Specialist's in field think that this is very inefficient power to weight ratio. So, this clause 'protects' inefficient development. Combined with the 400kJ limit per lap, these power restrictions will result in one limp overtaking attempt per lap, at best. So forget more spectacular racing. Drivers will just conserve their precious extra energy for the most obvious place to use it on each lap. The overtaker and the overtakee will have no relative advantage because they can both use they KERS, so everything will remain much the same. After all that technical effort, what a waste of talent is that? Maybe FIA will change this rule to free development of more efficient KERS.

But the FIA already anticipates that some teams will be able, if there are not limitations, to get as much as 120 bhp out of their surge power units by the end of 2009. By 2011 that might rise to over 300 bhp of surge power. As a result, the peak combined output of the car's power units could easily approach 1,000 bhp by late 2009. And that is too much. (Didn't happened. On the end of 2008, teams decided to temporary abolish use of the KERS during 2010, and reintroduce it for 2011. Specifications will be the same as for 2009, with possibilities of change during 2012).

In all KERS platforms, there must be at least 3 key components:

- energy

harvesting mechanism (motor / generator unit or Flywheels)

- energy storage medium ( battery assembly or supercapacitors)

- energy

delivery mechanism (motor / generator unit)

There is two probable ways to fit KERS. Using front wheels and connecting them to small gearbox fitted in the nose cone. Gearbox is connected to generator which generates electric power. Electric power is stored in batteries or capacitors, and used by electric motors fitted on the rear wheels or inside gearbox. (That was only one of possible ways, but actually never used. All teams used generator/electric motor connected to gearbox, and batteries in some convenient place)

It has been suggested that the FIA originally intended a capacitor-based system, with single-source procurement of a standard capacitor which would be sold on to the teams, who would then implement their own controllers and electric motors. However, some teams preferred alternative solutions such as hydraulic or kinetic energy systems, and the current FIA position is that the technology should be 'completely free', provided it is demonstrably safe. (None of this happened so far. Williams was the only team experimenting with Flywheel Torotrak - Xtrac Flybred system, but was never used in race. Actually, Williams created separate division to work on this system, Williams Hybrid Power, including commercial use, but on the end of season 2010, in one interview with Adam Parr, they concluded that for season 2011 they want to use battery powered unit because of packaging problems. Flywheel is bigger unit, and weight can't be distributed like with generator - electric motor - battery combo)

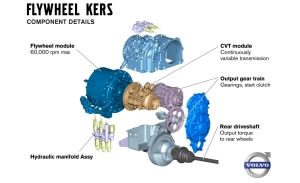

Second way is to use KERS system invented by Xtrac and Torotrak called Flybrid, or some similar system, on the rear wheels. Xtrac KERS system is basically a CVT connected to a flywheel that engages on deceleration, recuperating some of the energy that would otherwise be converted to heat in the brakes. This spins the flywheel up, which continues spinning until called upon to boost acceleration.

Under the rules, which go into effect in 2009, the driver can only use the boost provided by the KERS system for a predetermined amount of time and at an established rate, much like the 'Push to Pass' technology in Champ Car World Series racing.

Although it sounds relatively simple, the actual construction of the flywheel KERS unit is a marvel of complexity and compactness. Packing a flywheel and a full CVT transmission capable of withstanding Formula 1 power - and transmitting enough torque to meaningfully improve a car's already incredible performance - into a 5kg package, the Xtrac KERS is also dimensionally compact, an obvious necessity for applications inside the already tiny space of a Formula 1 car.

The 'variator,' as the CVT portion of the KERS unit is called, operates at over incredible 90 percent mechanical efficiency. Compared to the alternative of electrical-battery systems, the mechanical KERS system provides a more compact, efficient, lighter and environmentally-friendly solution. (As I explained before, mechanical KERS weight is all concentrated on one spot, and can not be distributed.)

The 'variator,' as the CVT portion of the KERS unit is called, operates at over incredible 90 percent mechanical efficiency. Compared to the alternative of electrical-battery systems, the mechanical KERS system provides a more compact, efficient, lighter and environmentally-friendly solution. (As I explained before, mechanical KERS weight is all concentrated on one spot, and can not be distributed.)

TERS thermal energy recovery systems are not allowed by the rules, for now. The manufacturers and the FIA also agreed to 'prepare draft regulations for devices to use waste heat and exhaust gases to assist the engines in propelling the cars', possibly for implementation as early as the 2010 season. (Didn't happened 2010, but included in new 1.6liter engin regulations from 2014.)

On FIA interview on Friday before Canadian GP on 08. June 2008, Geof Willis, technical director of RedBull Racing and Pat Simonds, technical director of Renault F1 Team, engine supplier for RedBull Racing, give some details of KERS system that will be incorporated to their cars:

…

Q: (Daniel Bastien - Radio FM 103.3) How far ahead are you with the energy recovery systems?

Geof Willis: Reasonably well underway. Clearly we know what the architecture of our energy recovery system is going to be and we know the type of technology that we are using. In our programme we will be able to test parts of the hardware in a few months time and then look towards final track testing at the end of the year in time for next year's car.Pat Simonds: We are probably in a very similar position. We have run the motor generator unit on a dyno connected to an engine. Layout of the car is going ahead with the positioning of batteries and stuff like that. There is a lot of software and a lot of simulation done. We are well into the safety aspects of the car which are very important on hybrid cars. There is a lot left to do and there doesn't seem much time to do it but I guess like always we will get it done.

…Q: (MC) Geoff, can I come back to you on that: are you doing it yourselves, as Red Bull Racing, or is your engine supplier doing it?

GW: It's certainly being done in close cooperation with Renault. The system is quite tightly connected with the whole powertrain. The battery technology itself is something that we're developing independently but we're using very similar solutions to Renault Enstone, and as Pat has said, we have the same - as most of the teams using this type of technology are going to be using - we have the same challenges of safety, of appropriate packaging. The battery packaging in the car will be quite a challenge. The sheer volume of battery we have to package is not trivial, even with next year's aerodynamic regulations, it's still a bit of a struggle to find a safe and aerodynamically effective place to package it, so it's quite a big challenge, for sure.

…Q: (Joe Saward - Grand Prix Special) Pat, to follow on from what was just being said about the new systems being developed, and about what's been happening at Viry Chatillon, it's a strange time to be cutting back on engine R&D when we have new systems needing to be developed and then ultimately new engines in 2013 and perhaps even 2011. Can you talk us through exactly what's going on, what changes are being made and how long it takes to work on a new engine?

PS: Yes, there are two separate things here. The Kinetic Energy Recovery Systems are very much an Enstone-based development group. Now of course they have to work with the engine, it is a powertrain project but it's largely Enstone-based, so there's not a huge knock-on effect on the engine. We are of course allowed to modify the engine to fit the KERS systems, and there are designers involved in doing that.

…Q: (Niki Takeda - Formula PA) Pat, can you just expand on packaging and positioning of the battery for KERS? Obviously, you don't want any failure close to the fuel tank.

PS: Yes, the KERS project is actually quite fascinating. It's rare that we get a chance in Formula One to do something really different. We've spent many years producing cars that are ultimately similar. We may have changed from turbocharged engines to normally aspirated engines. We may have had slick tires and grooved tires and things like that, but KERS has introduced a lot of new things and the battery technology is a very interesting one. I think batteries recently, particularly lithium ion batteries, have had quite a lot of bad press from laptop computers catching fire and things like that. It's a very real worry. The management of the state of charge of the batteries is very very important. As Geoff said, they are very difficult to package. There are a lot of little batteries that we've got to put in the car somewhere, trying not to have too much aerodynamic deficit. We've got to keep them cool. Even if you keep the state of charge good on them, you've still got to cool the things to get efficiency. The whole thing is quite an interesting project, it's the sort of thing I like to see.

Renault, Ferrari, BMW, RedBull Racing and some other teams decided to go with Generator - Batteries - Electric motor combination. If you ask me, like electrical engineer, my opinion of this combination is not ideal. Batteries are weak link in this chain. Battery technology is still not efficient enough, and weight to Amper/hour (capacity) ratio is still on negative side, and for sure they will need additional water or air cooling. Spill of acidy substances during accidents can be very dangerous. Packing of enough batteries and their shape can be a problem. Lithium polymer batteries can be packed at any shape, but technology is still very young and expensive even for F1. Think of price of the battery for your mobile phone. So small and so expensive. I think that much better solution is capacitor.

Ferrari was using system supplied by Magneti Marelli

The regulations stipulate that the release must be completely under the driver's control. There will be a boost button on the steering wheel which can be pressed by the driver.

The use of KERS is not compulsory for 2009. Given that the ultimate costs and benefits of the system remain somewhat unclear, do not be surprised if some team's 2009 machine's do not use KERS. (Only Ferrari, McLaren, BMW and Renault were using KERS more or less regularly throughout the 2009 season)

Will KERS make the car go faster, the short answer was always going to be "no"! With reference to article 5.1.3 of the 2009 regulations, the engine speed cannot exceed 18,000 RPM. Hence by knowing the different rotational speeds in the drive train, it cannot cause the engine to rev beyond this limit. And car speed is limited by rotational speed of the engine/gearbox output speed. As such top speed of the car will not be affected. What we do see however is an increase in the torque that the car can in fact produce. With KERS and its additional torque and power, we will see the torque, during KERS activation period, at the rear wheels increase for around 20-25%. As a result of all this freshly added torque, the car will accelerate to gear change point much faster, assuming the rear wheels are able to maintain traction. So, the whole point is to provide the car with additional torque and more capability for faster acceleration, however as discussed earlier the car maximum speed is limited to a maximum engine/gearbox output speed.

That's what was on the beginning of the season 2008, when nobody have a clue about future use of KERS. Idea is here, and also principle of work.

Now we can see how it paned out during 2009 season and after that.

The KERS story began at the tail end of 2008, during the testing sessions, when BMW were ‘pioneering’ the technology and consequently nearly killed one of their mechanics when the system didn’t discharge properly and promptly made the whole car electrified.

According to BMW Sauber, the reason behind the KERS electric-shock incident, seen above, which occurred during testing at the Jerez speedway, was magic. Or at least, that’s what the formal explanation looks like if you don’t have at a solid knowledge of electrical engineering. It sounds like the combination of a bad KERS controller and a leaky capacitor led to some extra electrons floating around. Deadly? No. Enough to shock the crap out of someone, though. Here is explanation from BMW, in highly coded language, tyipicaly for an Formula 1 engeneer:

“The mechanic suffered an electric shock after touching the sidepod and steering wheel of the car. There was a high frequency AC voltage between these contact points, the cause of which has been traced back to the KERS control unit and a sporadic capacitive coupling from the high-voltage network to the 12-volt network. The voltage ran through the wiring of the 12-volt network to the steering wheel and through the carbon chassis back to the control unit.”

All Clear????

Kinetic Energy Recovery Systems (KERS) were used for the Formula One's 2009 season. KERS is to be reintroduced next season after the teams mutually agreed to suspend its use in 2010. The Formula One Teams that used Kinetic Energy Recovery Systems in the 2009 season are Ferrari, Renault, BMW, and McLaren. One of the main reasons that not all cars use KERS is because it adds an extra 25 kilograms of weight, while not adding to the total car weight, it does incur a penalty particularly seen in the qualifying rounds, as it raises the car's center of gravity, and reduces the amount of ballast that is available to balance the car so that it is more predictable when turning. It was a loss of ballast flexibility that was widely held to disadvantage with heavier drivers, such as Mark Webber and Robert Kubica, when KERS was a feature of F1 in 2009. BMW, for instance, ran a KERS system on Nick Heidfeld's car but not on Kubica's exsactly because of that. Red Bull, like Brawn, opted not to run the system at all in 2009 and there was a feeling among some teams that the systems should either be compulsory or, as per 2010, not run at all.

The challenge for the engineers this time round will be packaging. Last time KERS was run, refuelling was legal. Now, with it banned, fuel tanks are larger and finding room to accommodate battery packs etc won’t be as easy. New rules for the 2011 F1 season raise the minimum weight limit of the car and driver by 20kg to 640kg. This is to give some ballasting flexibility to the teams. The weight limit will increase but the increase is not sufficient to cater for the extra weight of a KERS system and the car undertay reinforcement. And KERS works by harvesting energy from the car's driveshaft when the driver is off the accelerator and if KERS system became faulty car can became unpredictable under braking without it. The problem is that it's not just when you accelerate, it's when you brake. When you have KERS you have a lot of engine braking helped with KERS and when you don't have it, you don't have any braking performance. So every time driver arrive at a corner he didn't know what he was going to get, engine braking or not, and it can be pretty tricky.

|

|

McLaren Mercedes Battery Pack with water cooling system and PCU (Pover Control Unit) |

Vodafone McLaren Mercedes became the first team to win a F1 GP using a KERS equipped car when Lewis Hamilton won the Hungarian Grand Prix on July 26, 2009. Their second KERS equipped car finished fifth. At the following race Lewis Hamilton became the first driver to take pole position with a KERS car, his team mate, Heikki Kovalainen qualifying second. This was also the first instance of an all KERS front row. On August 30, 2009, Kimi Räikkönen won the Belgian Grand Prix with his KERS equipped Ferrari. It was the first time that KERS contributed directly to a race victory, with second placed Giancarlo Fisichella claiming "Actually, I was quicker than Kimi. He only took me because of KERS at the beginning".

Ferrari KERS battery pack

Despite pressure from the likes of Ferrari to increase the power of KERS systems, it has been proposed that 2011 spec KERS will remain as it was in 2009 - 60 kilowatts with a discharge of 400 kilojoules per lap. It will, however, remain optional rather than compulsory. A 5m Euro development budget per KERS system is to be imposed and teams who are buying one, have a budget ceiling of 1m Euros. Any team running their own system must also be able to prove to FOTA (Formula One Teams Association) that they can operate it for the season for 1m Euros but they are not forced to sell systems to teams which may enquire.

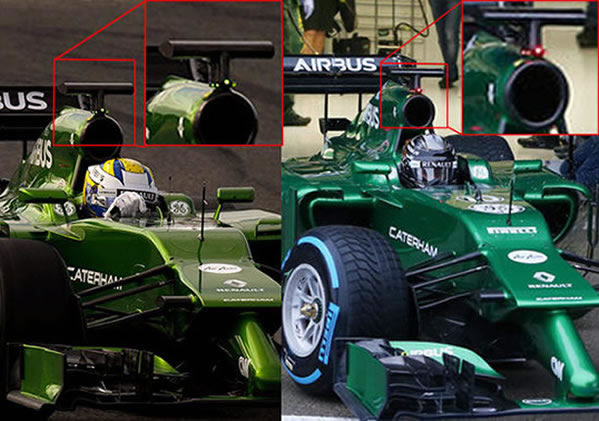

To prevent accidents like one explained before in Williams pit lane and to prevent that marshals don't run the risk of an electrical discharge from the car, FIA issued new rule for 2014, more powerful ERS system. From 2014, all cars must be equipped with red and green signal light on the rollhoop below upper camera pod. When ERS is armed and car is unsafe to touch LED light is red, and when car is safe to touch light change to green. You can see how it looks like on Caterham CT05, pictures taken during preseason Jerez test in February 2014.

To learn more about new 2014 rule change, new Formula 1 Power Units and new ERS System follow this link.

Audi R18 e-tron Quattro

Flywheel KERS Hybrid System (2012)

From 16th to 17th June 2012, the 24 hours of Le Mans has taken place at the Circuit de la Sarthe for the 80th time, and again Audi didn’t mind pushing the envelope a little further than most constructors would and has proven that with the release of a new Le Mans race car. Audi has captured all three spots on the podium (four of first five) thanks in part to its diesel-hybrid R18 e-tron race cars. This marks the first time in the race's illustrious history that a hybrid has come out on top of the pack.

"This is no doubt a historic victory for Audi," said Dr. Wolfgang Ullrich, the head of Audi Motorsports. "We were the first to win Le Mans with a direct-injection turbo gasoline engine and the first to be successful with a diesel engine. It’s a great result that Audi is now the first brand to have achieved victory with a hybrid vehicle."

For 2012, Audi introduced an evolution of the R18 TDI, last year Le Mans winner, called the R18 Ultra and the R18 e-tron Quattro. R18 e-tron Quattro is equipped with KERS with two additional electric motors and a flywheel to store and distribute the generated energy. To elaborate on this, and to try to explain everything we know for now about this two amazing cars, read my article here.